Nadcap Destructive and Non-Destructive Testing

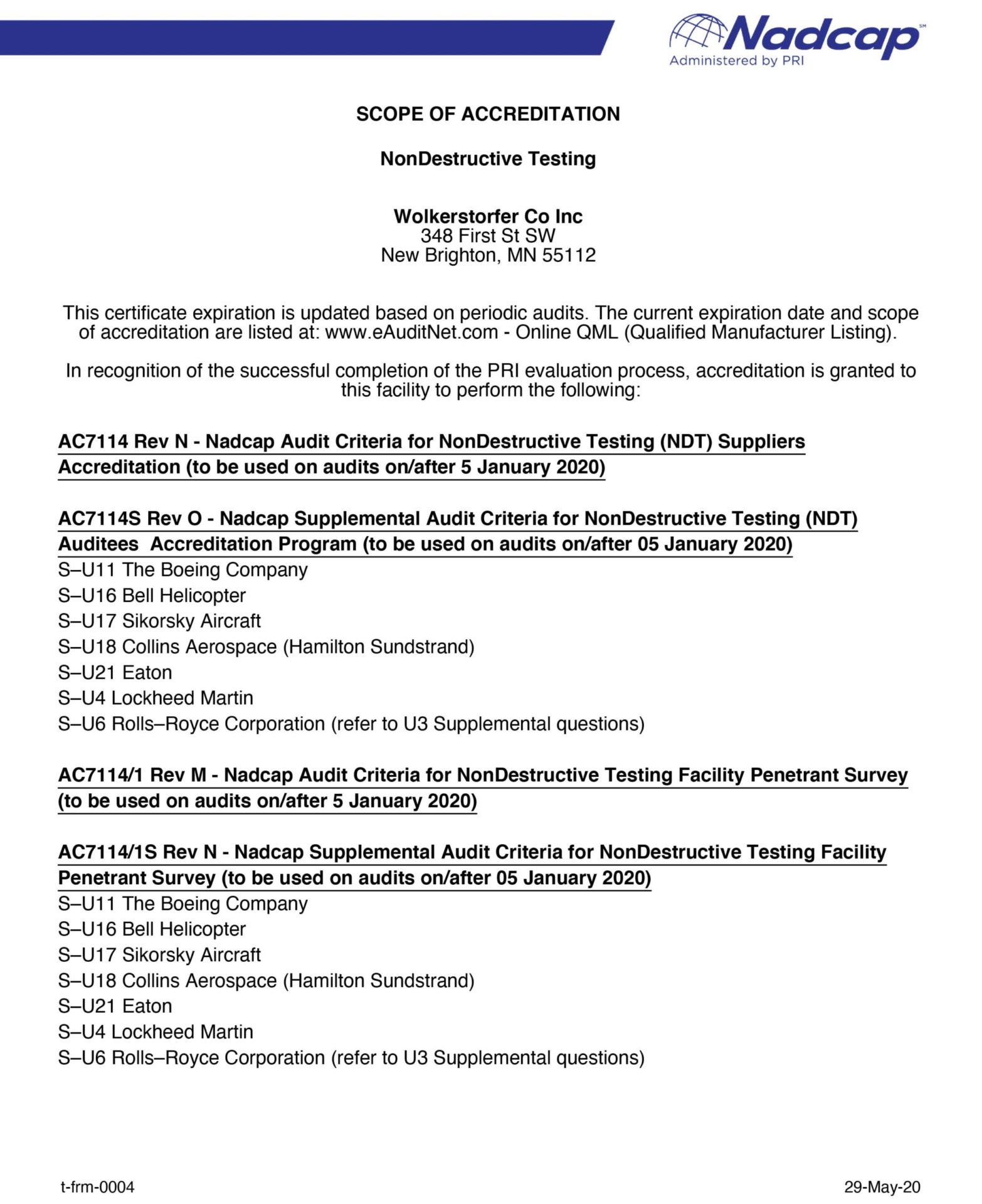

Testing, whether it is destructive or non-destructive, provides the end user a degree of confidence that the part that is being tested has no inherent flaws in it that may cause premature failure in its particular application. A stress crack in a part or a coating system that was not applied properly can have devastating results. Wolkerstorfer Company offers destructive testing, such as salt spray, cross hatch scribe testing and others to validate the coating systems we apply meet the applicable specifications. We also offer non-destructive testing such as fluorescent penetrant inspection, copper sulfate, and conductivity testing. These tests allow us to determine the presence or absence of a coating, and to identify defects in the material used to make the part.

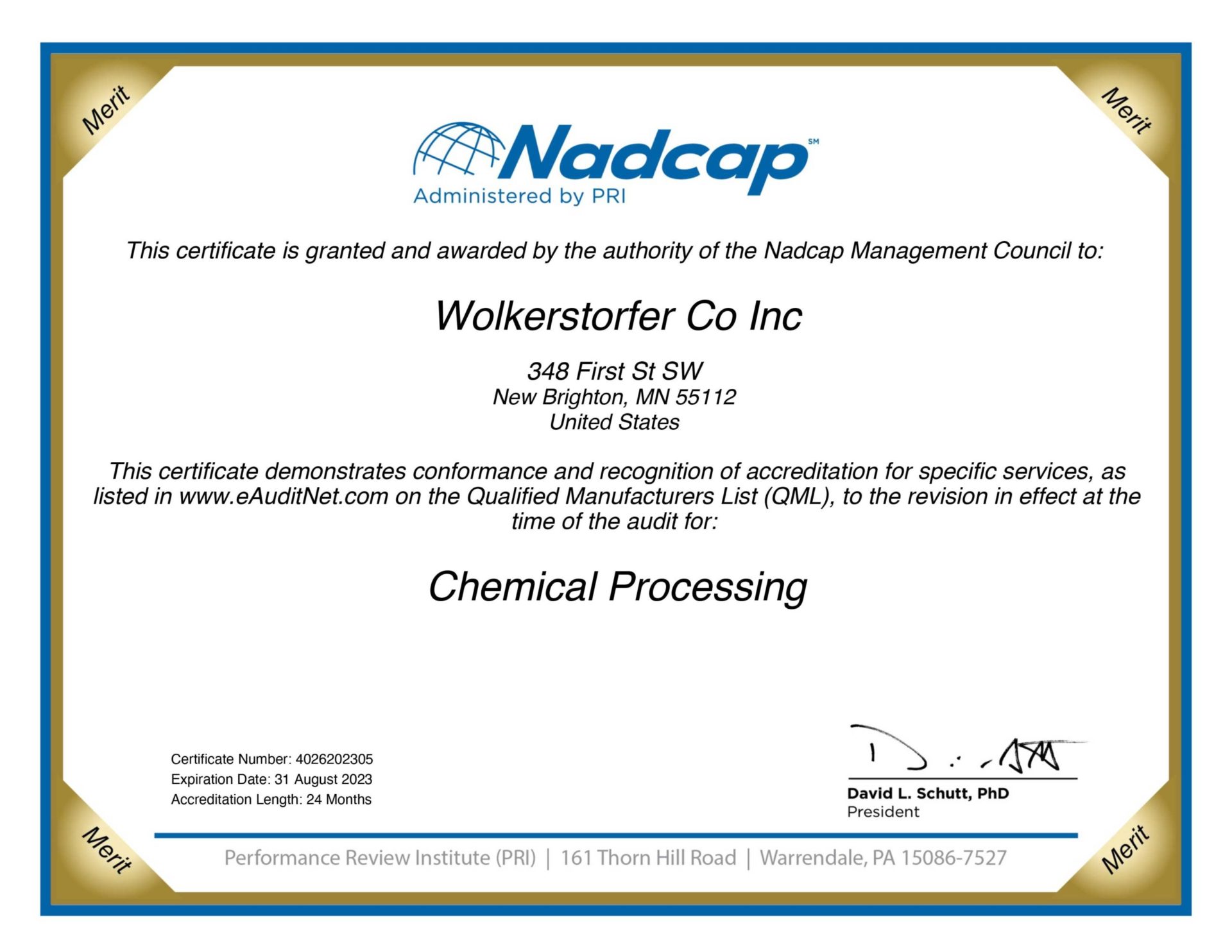

The FPI lines, including the pre-etch, are Nadcap certified (AC7114).

Penetrant

Inspection

Support

Testing

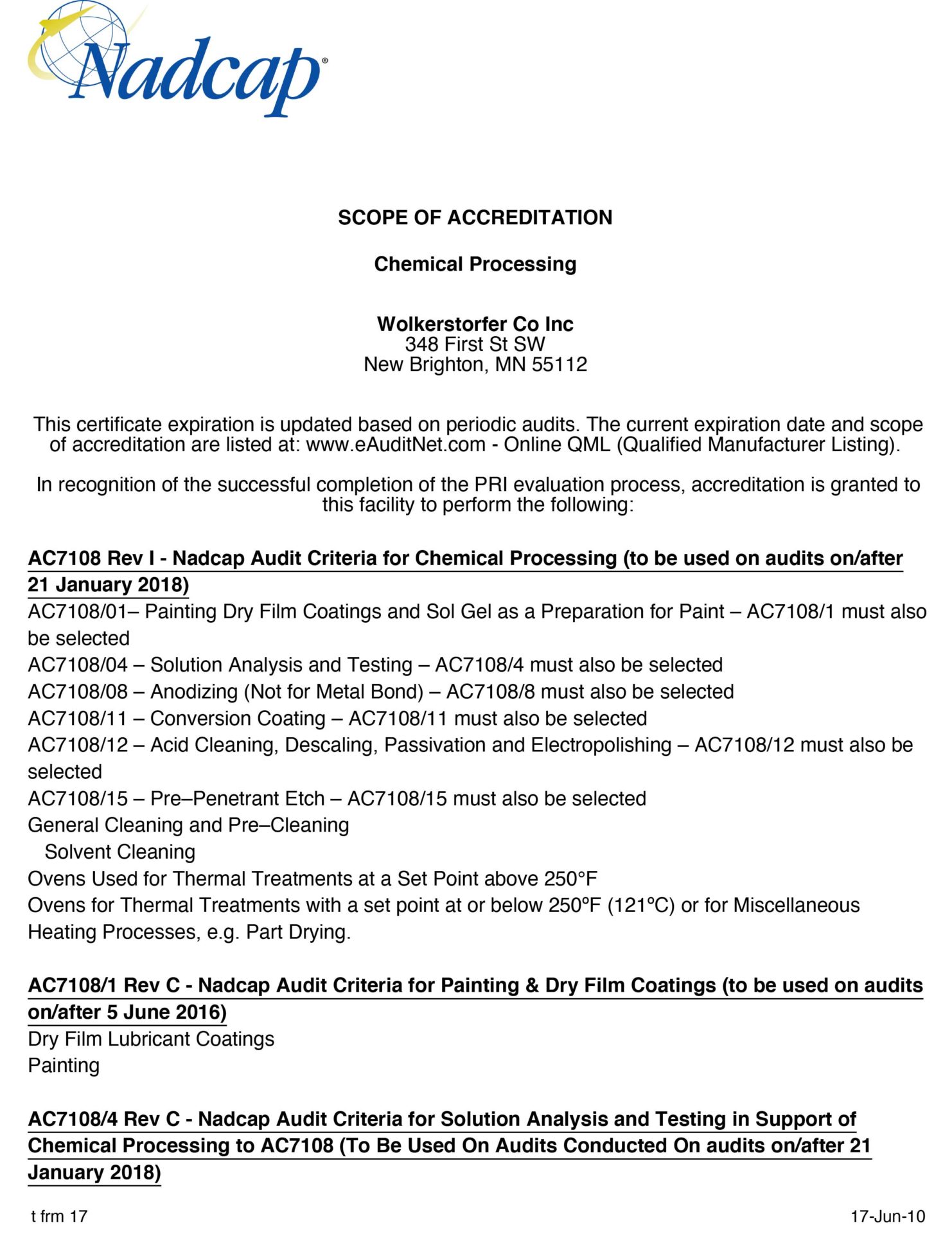

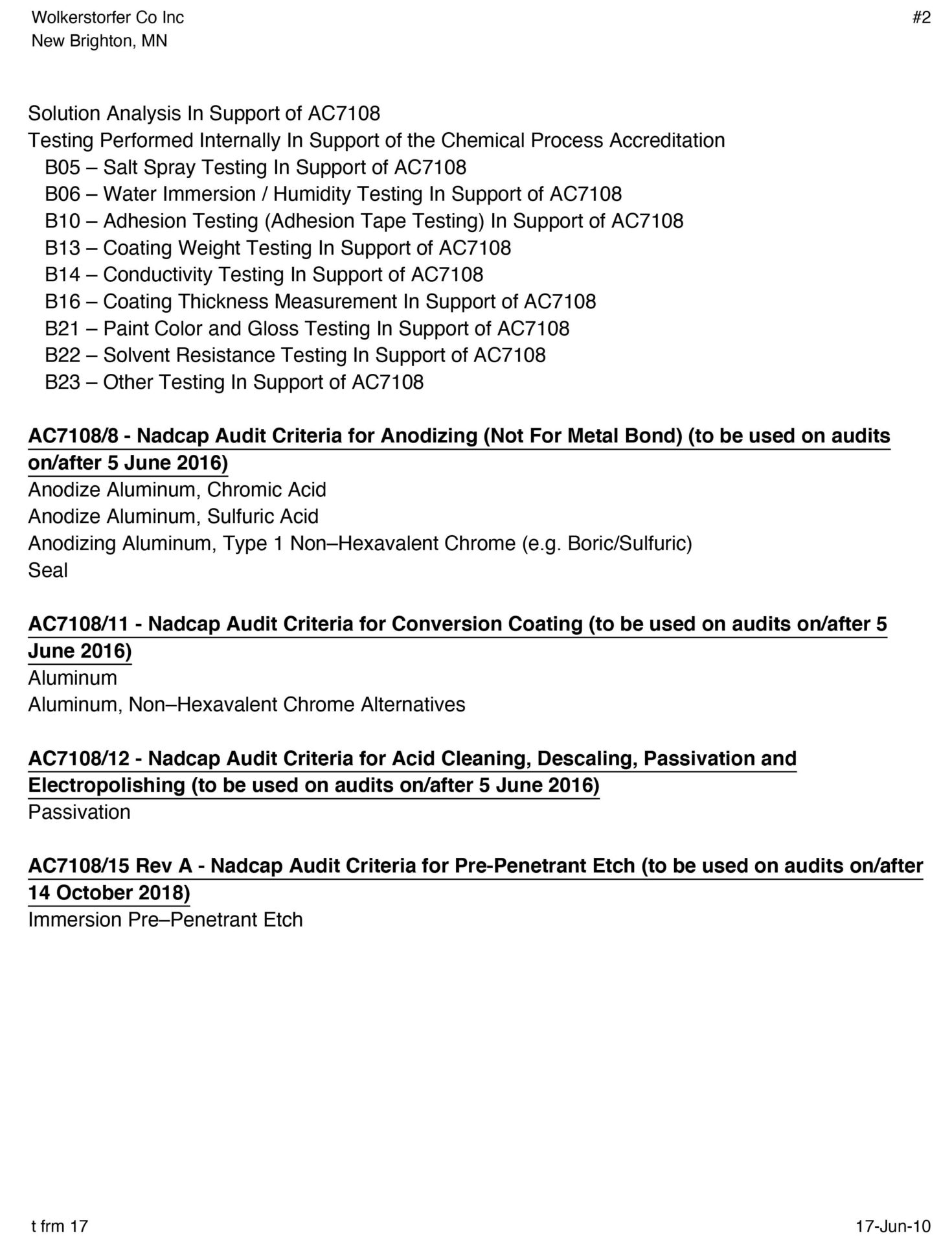

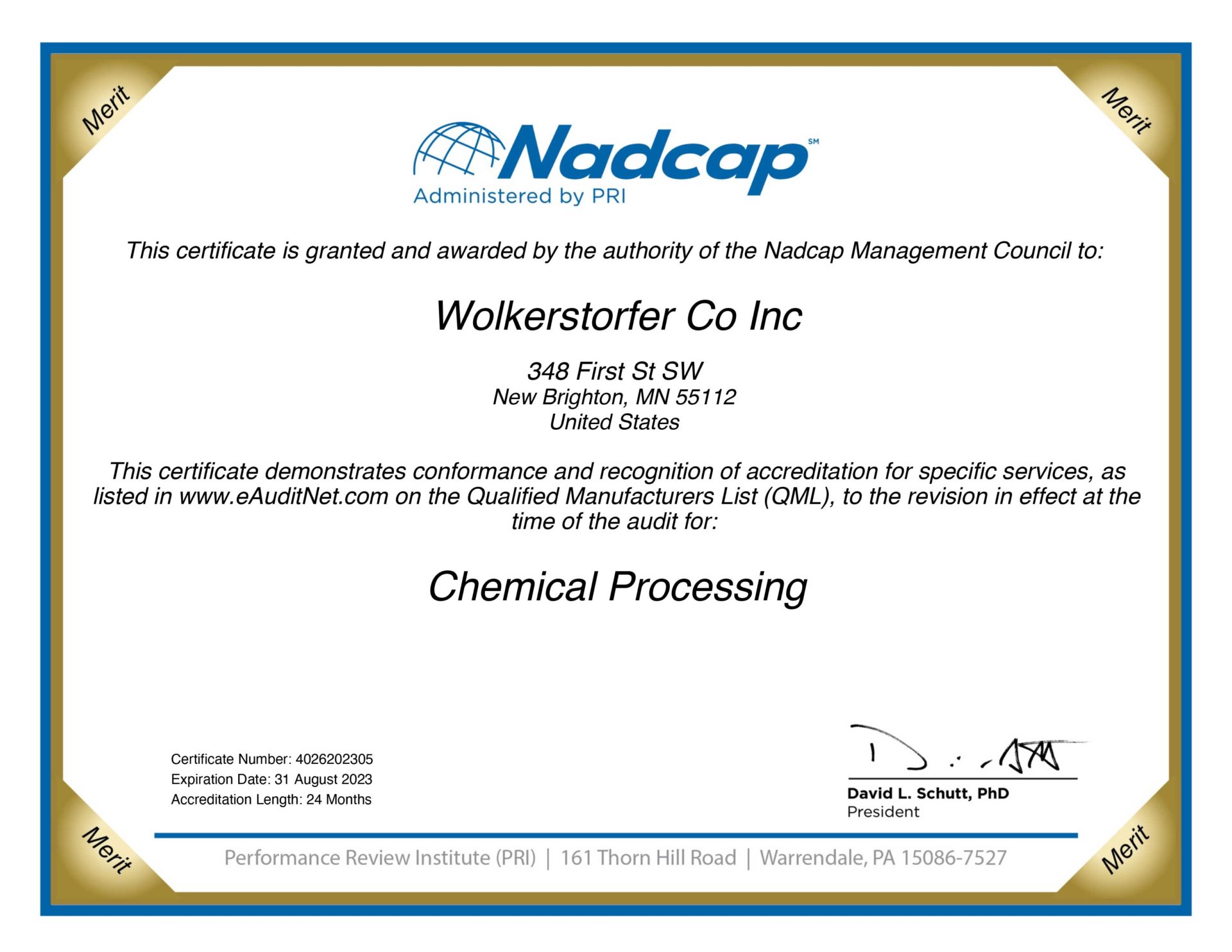

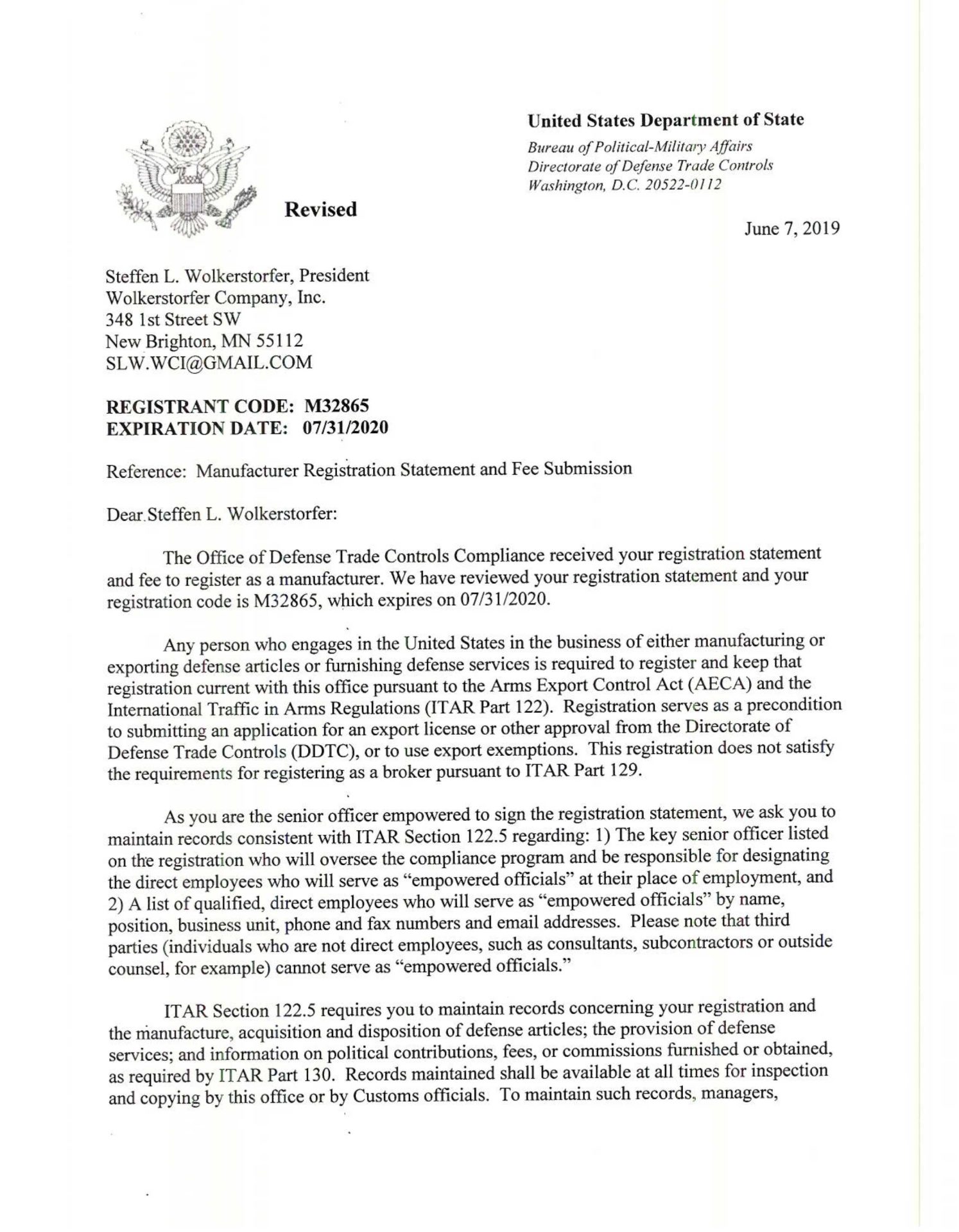

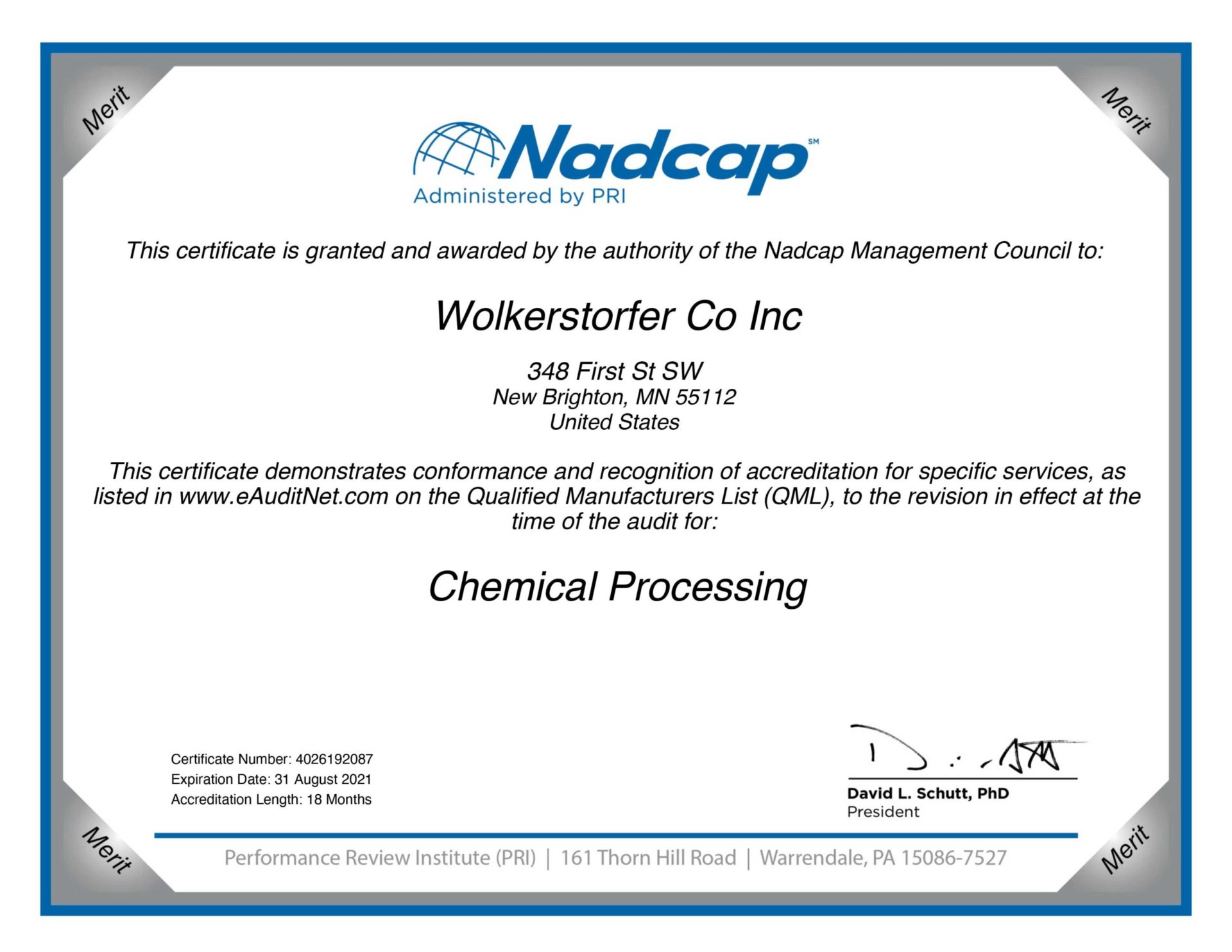

Nadcap Quality Systems / ITAR Registered

Click here to view our Nadcap Accredited / ITAR Registered Information.

The “Wolkerstorfer Way” – Exceptional quality with responsive lead times.

Note to consumers: Wolkerstorfer Company provides metal finishing services to the industrial and commercial marketplace. We do not offer painting or plating services for consumer and household items such as: automobile parts, motorcycle parts, jewelry, kitchen/bath fixtures and furniture. Thank You.