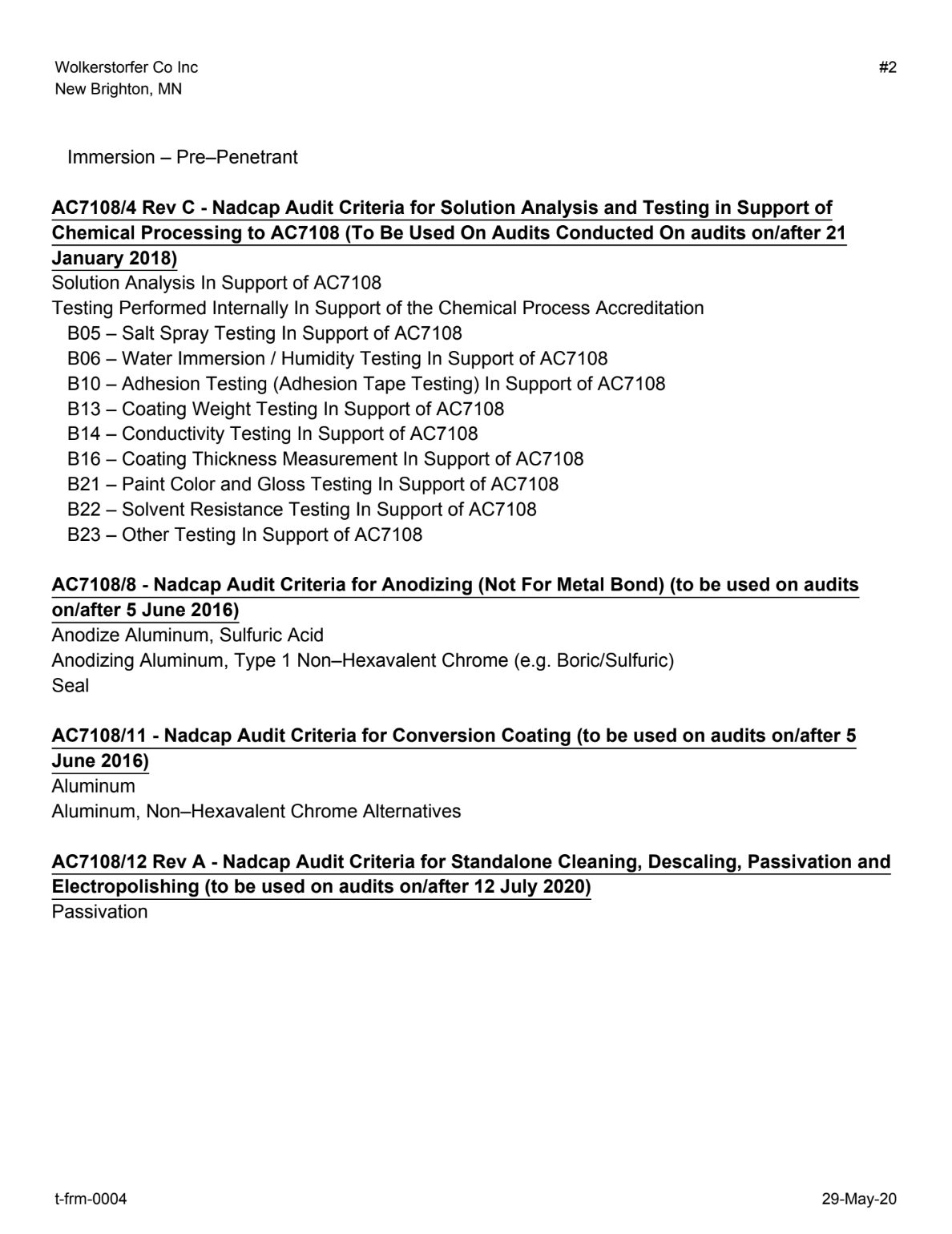

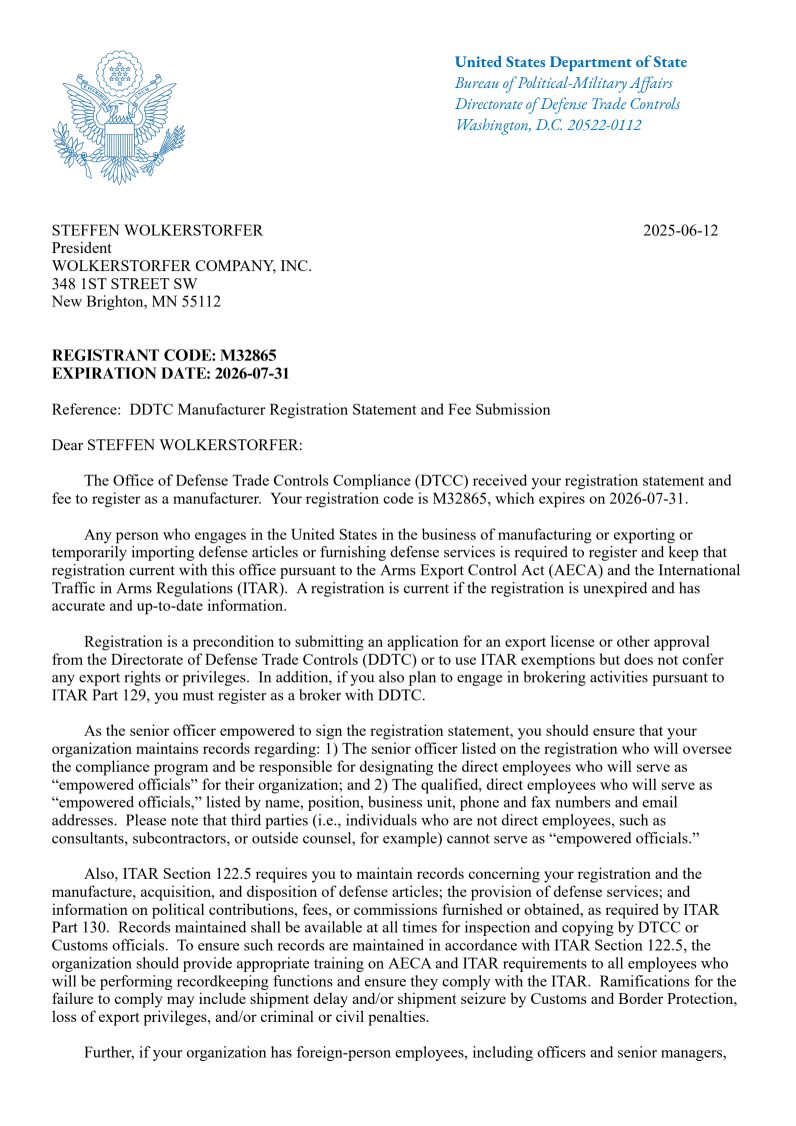

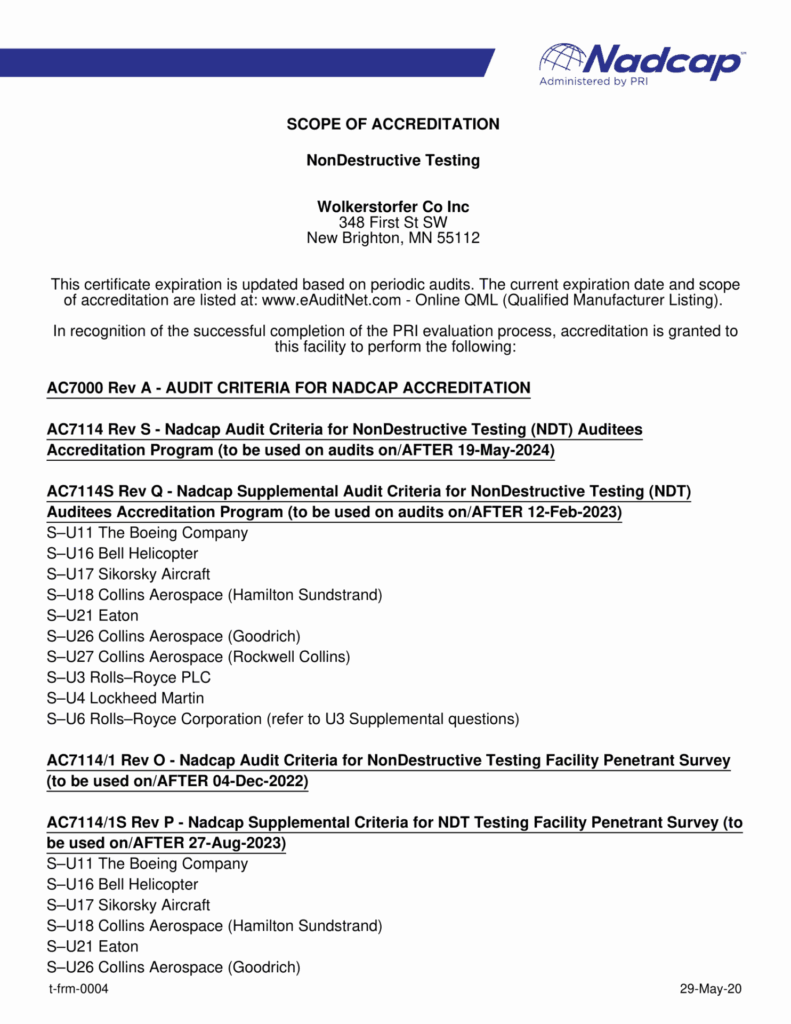

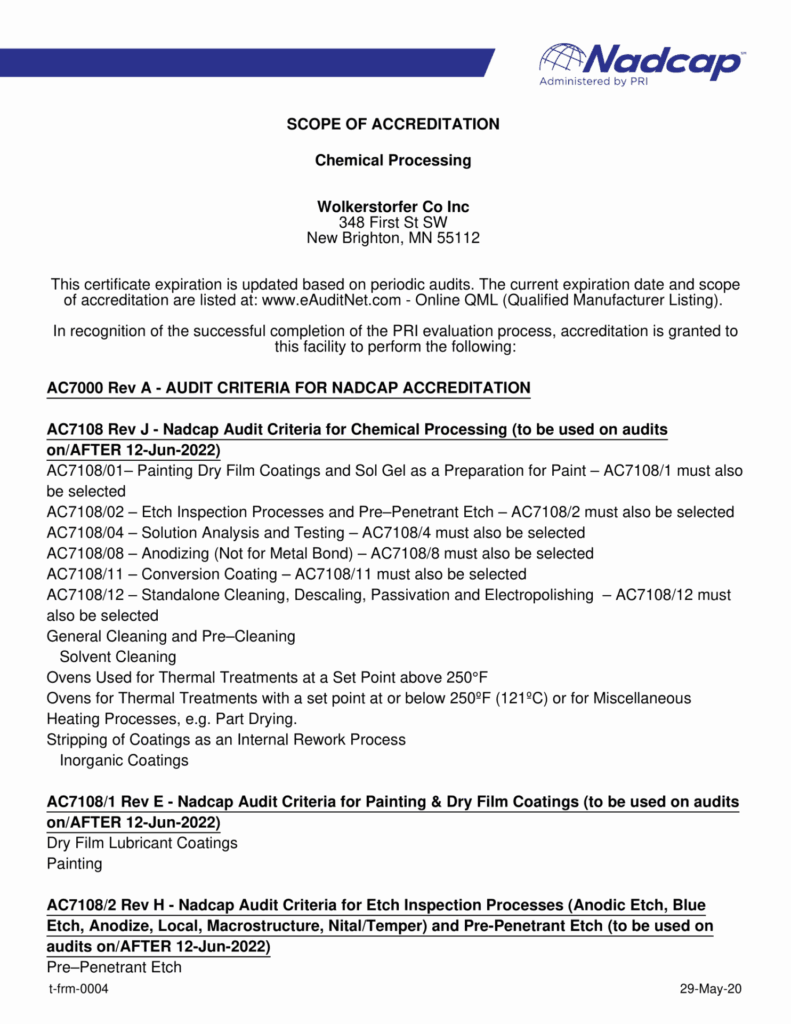

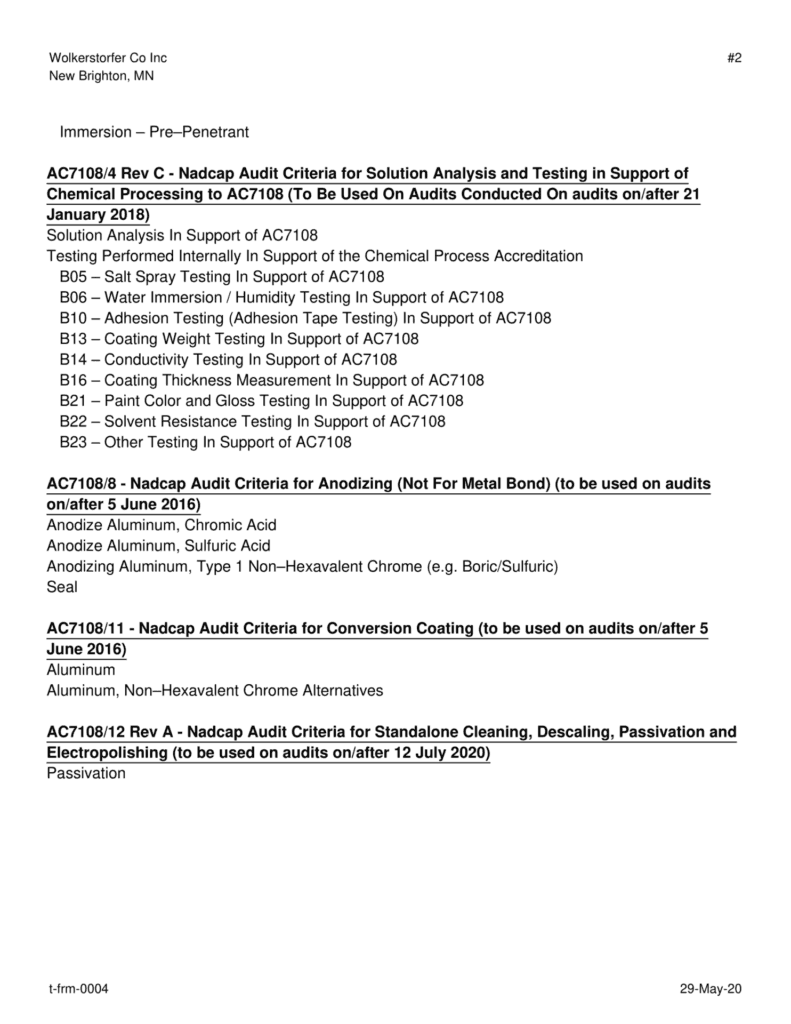

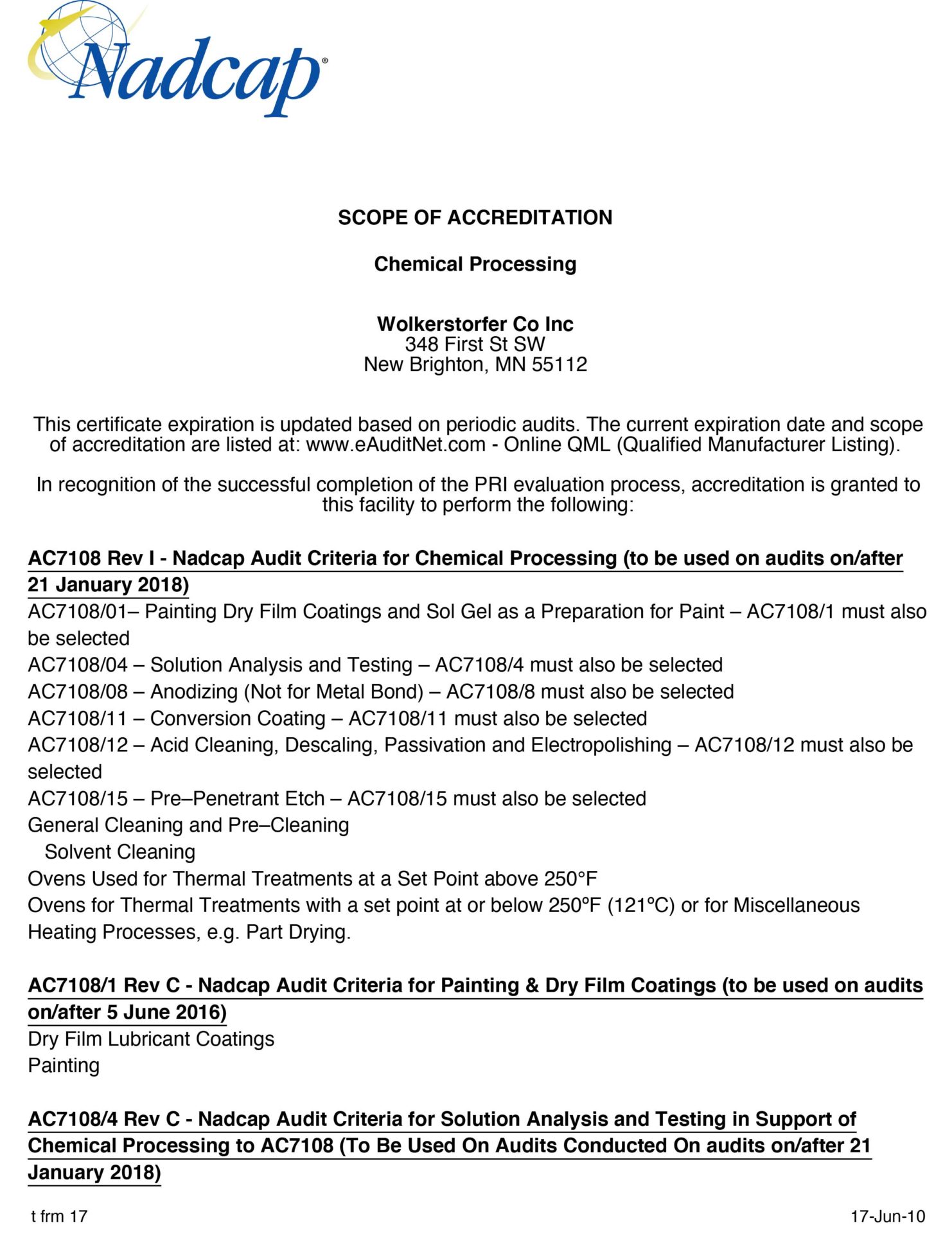

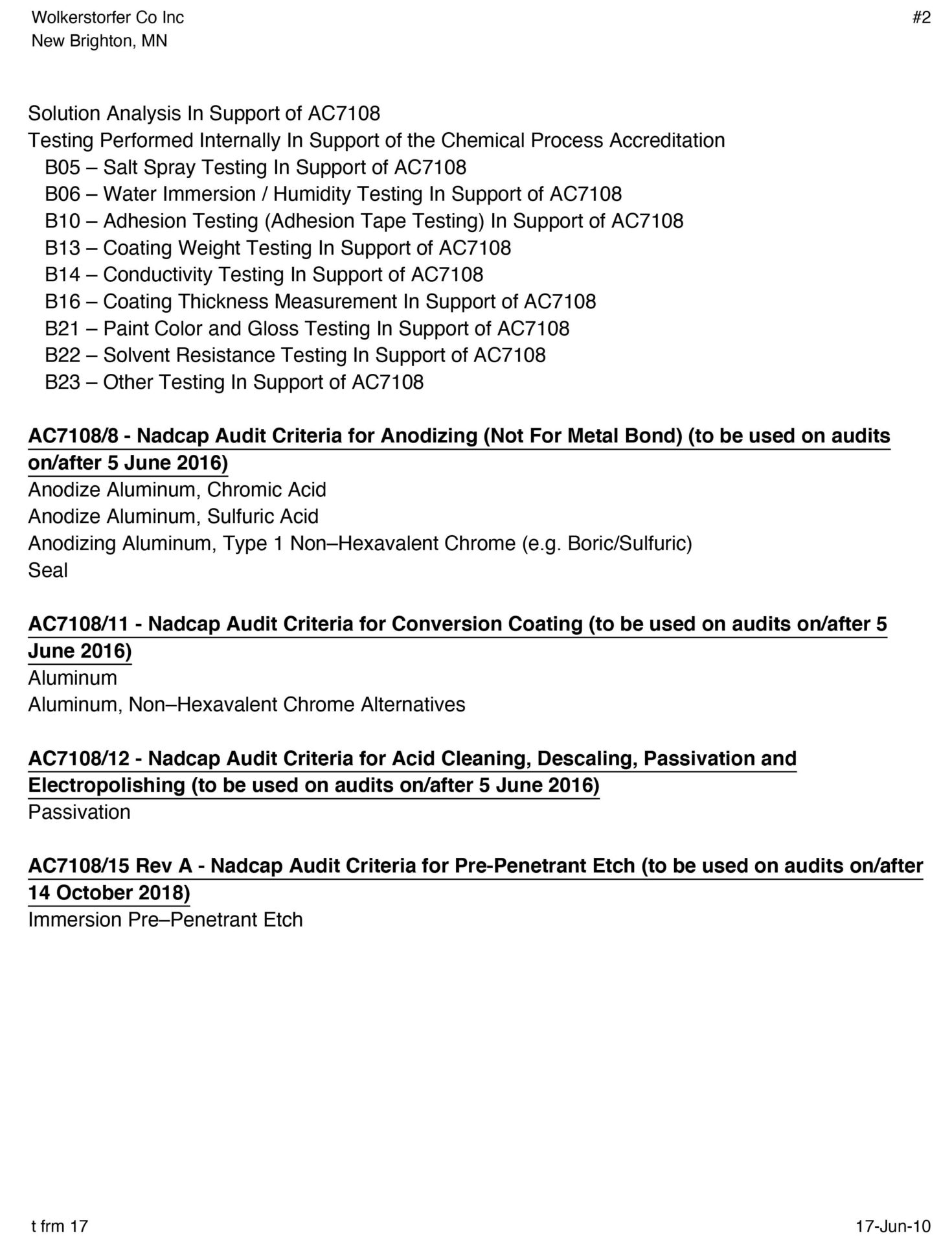

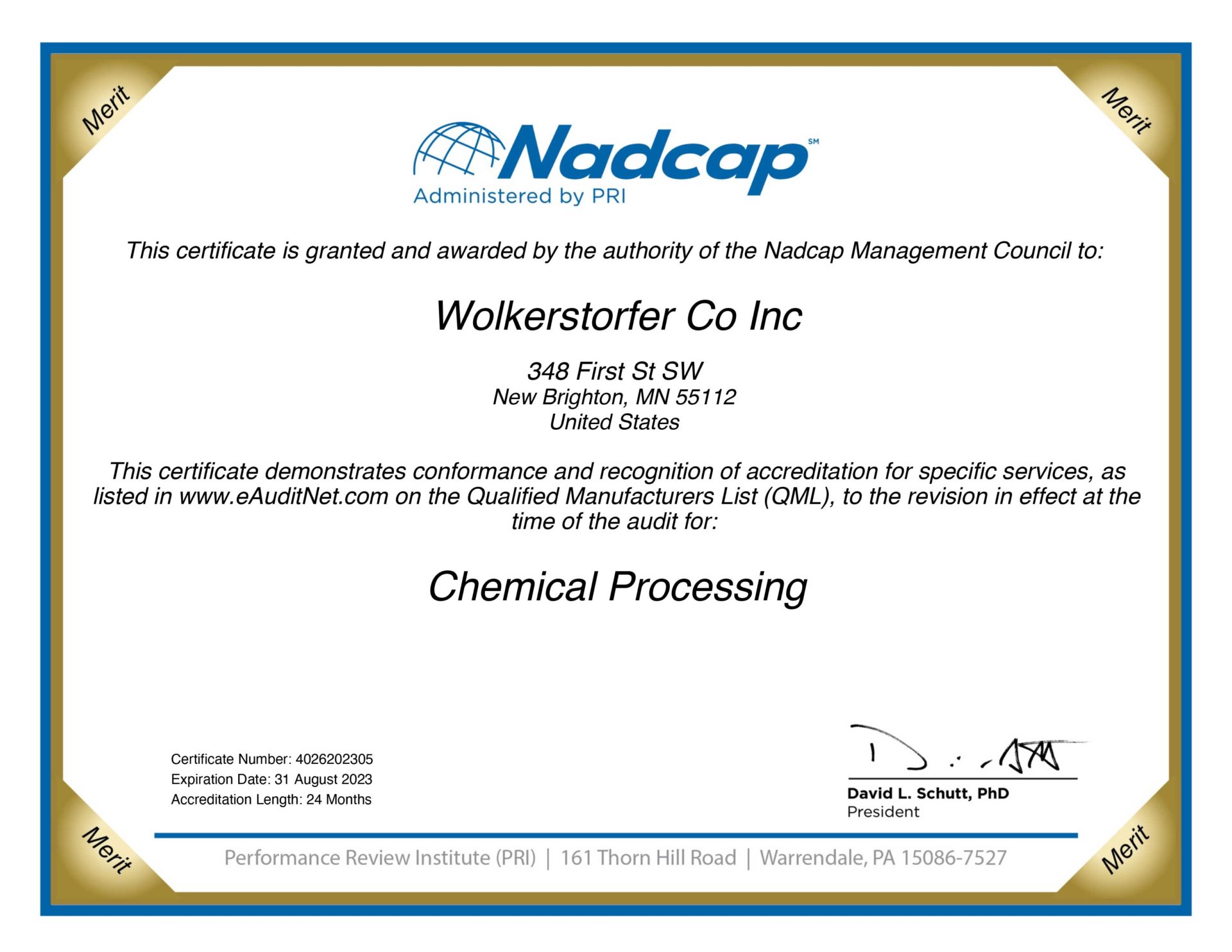

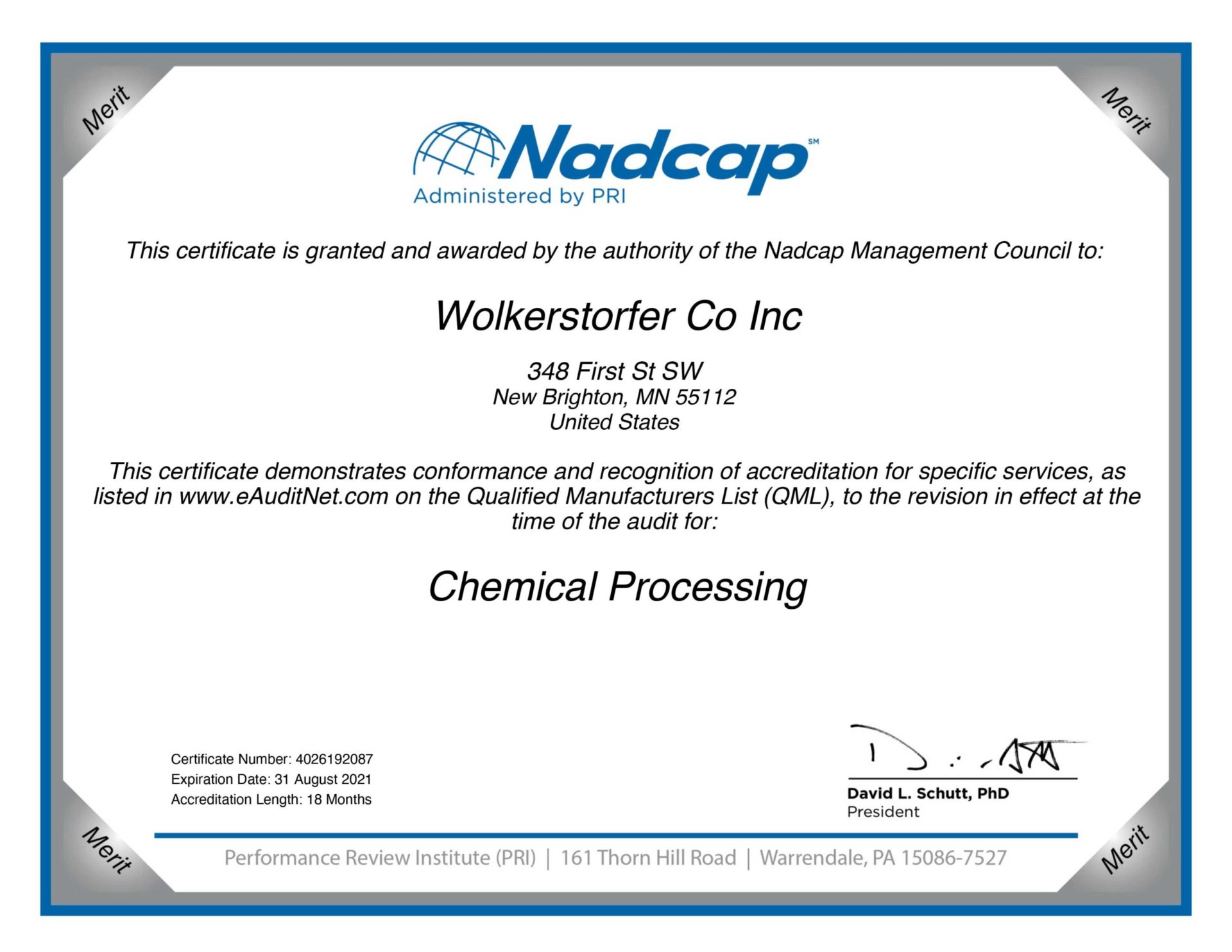

Nadcap Certified Painting, Plating, and Fluorescent Penetrant Inspection

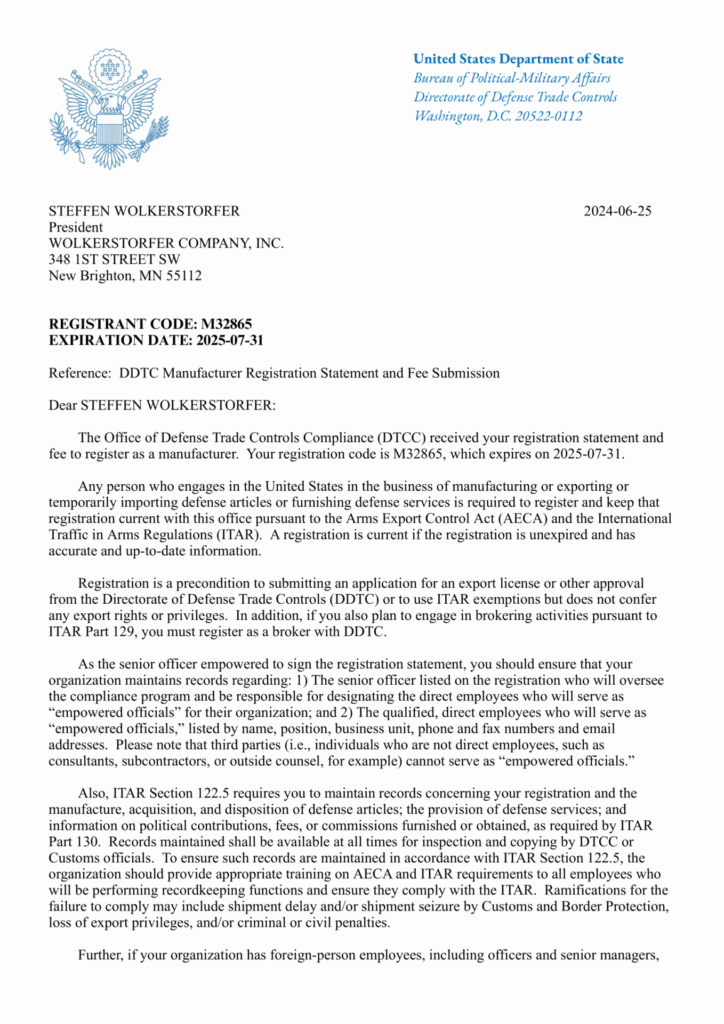

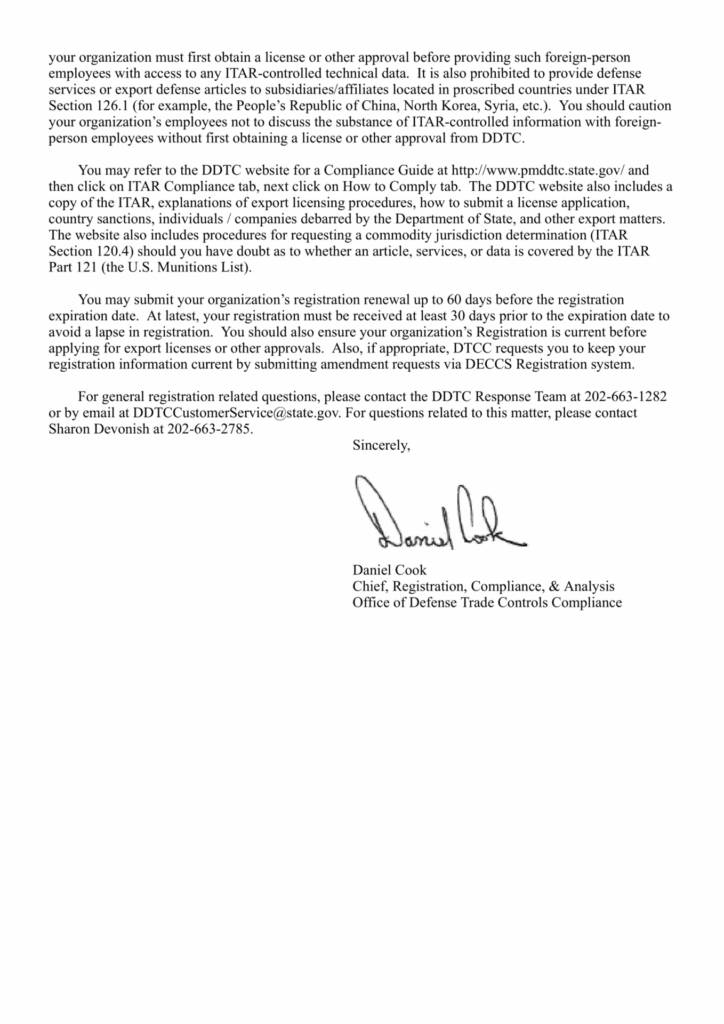

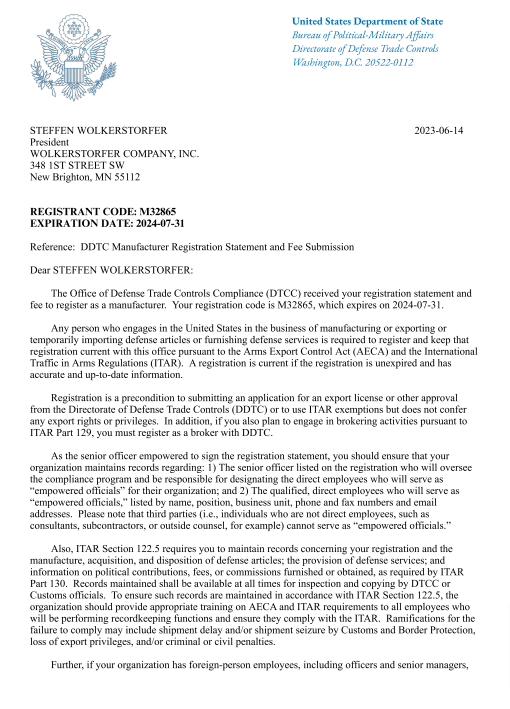

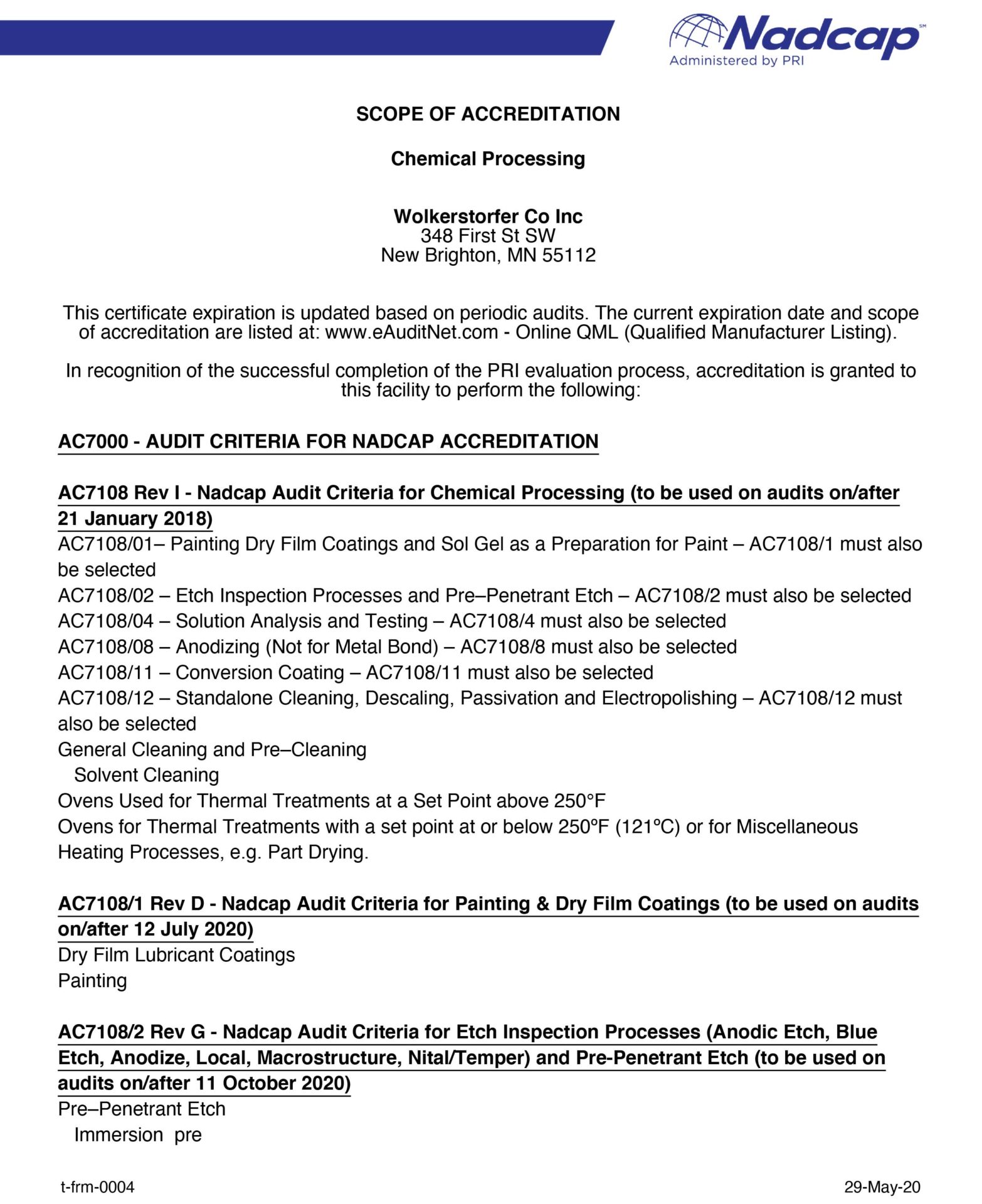

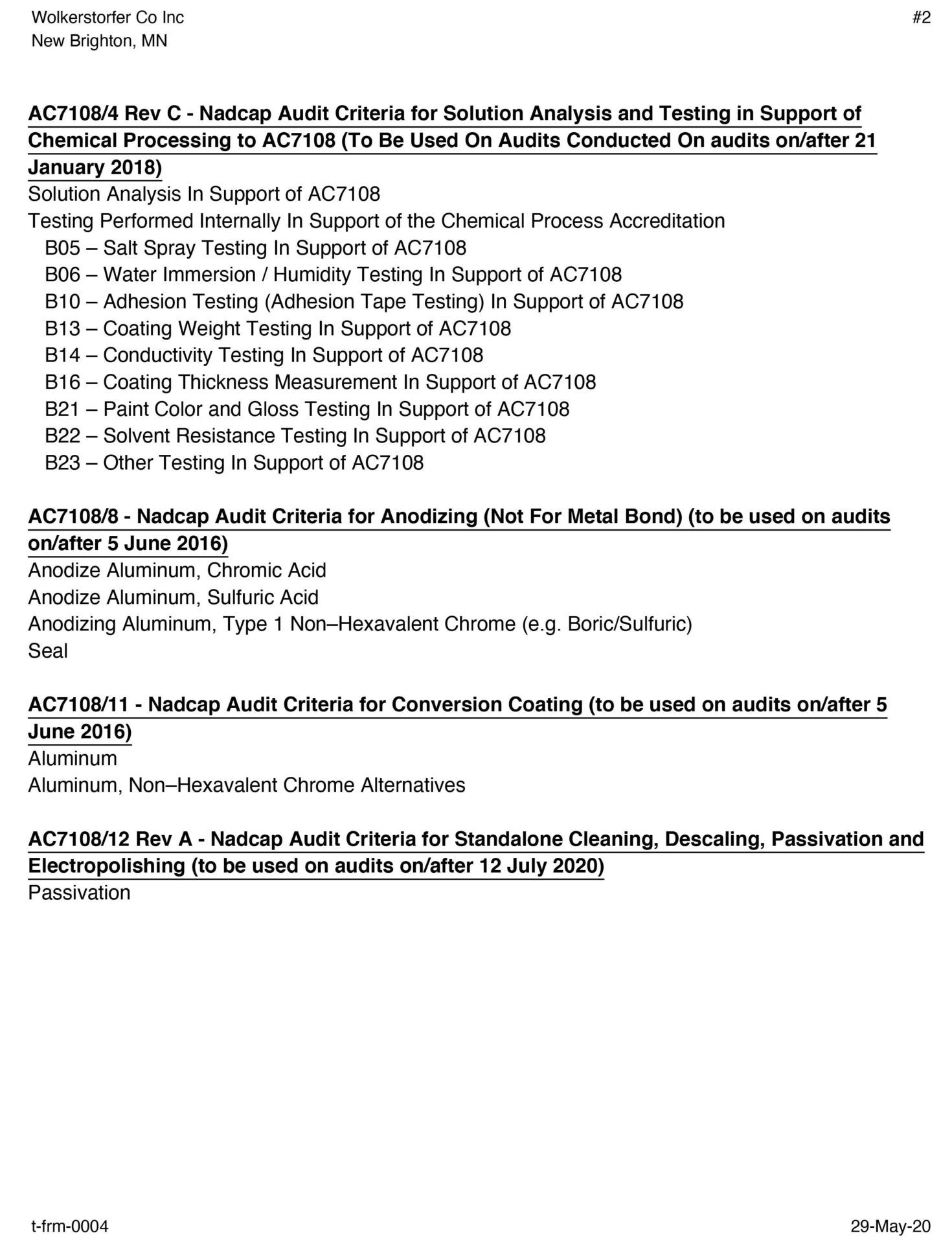

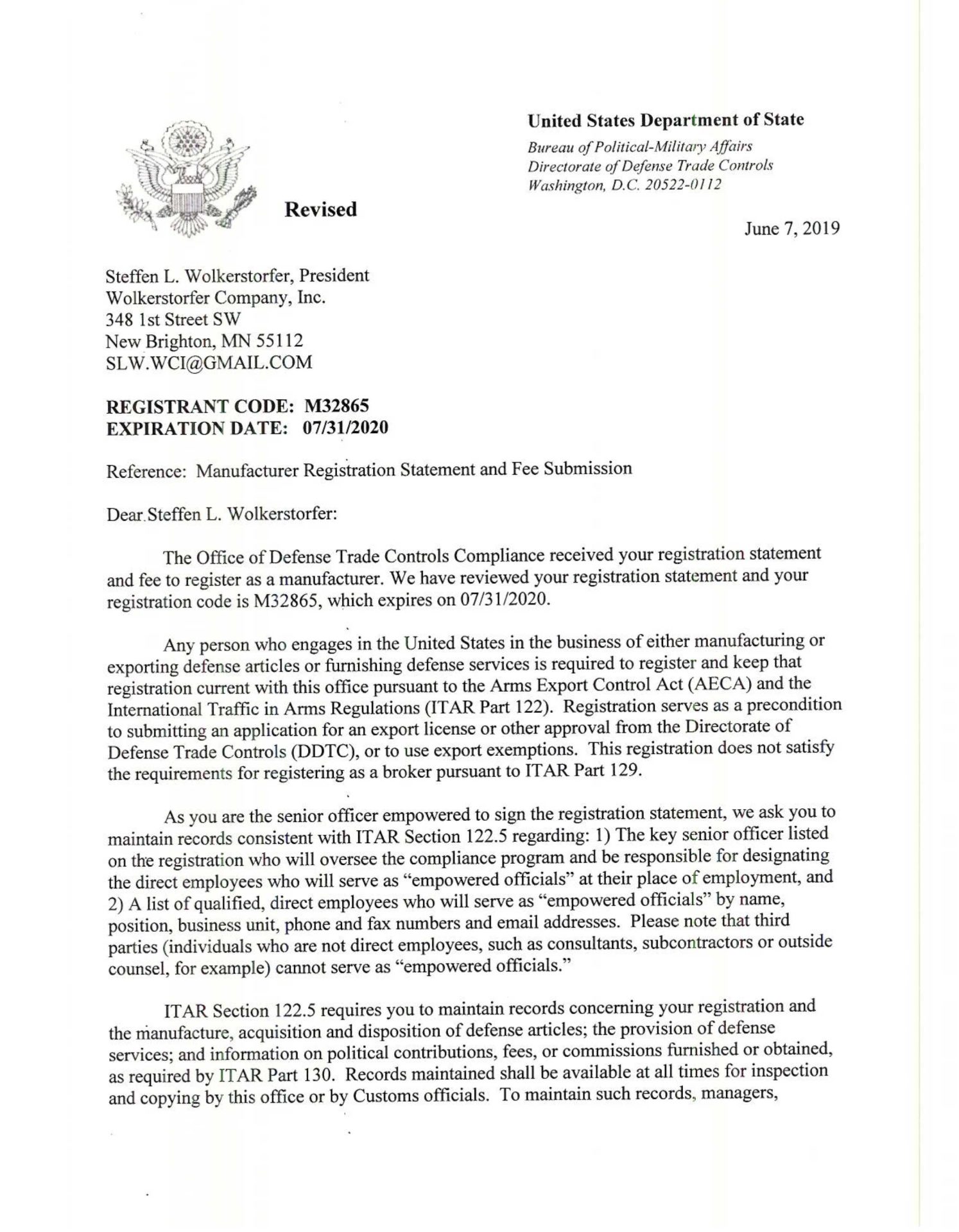

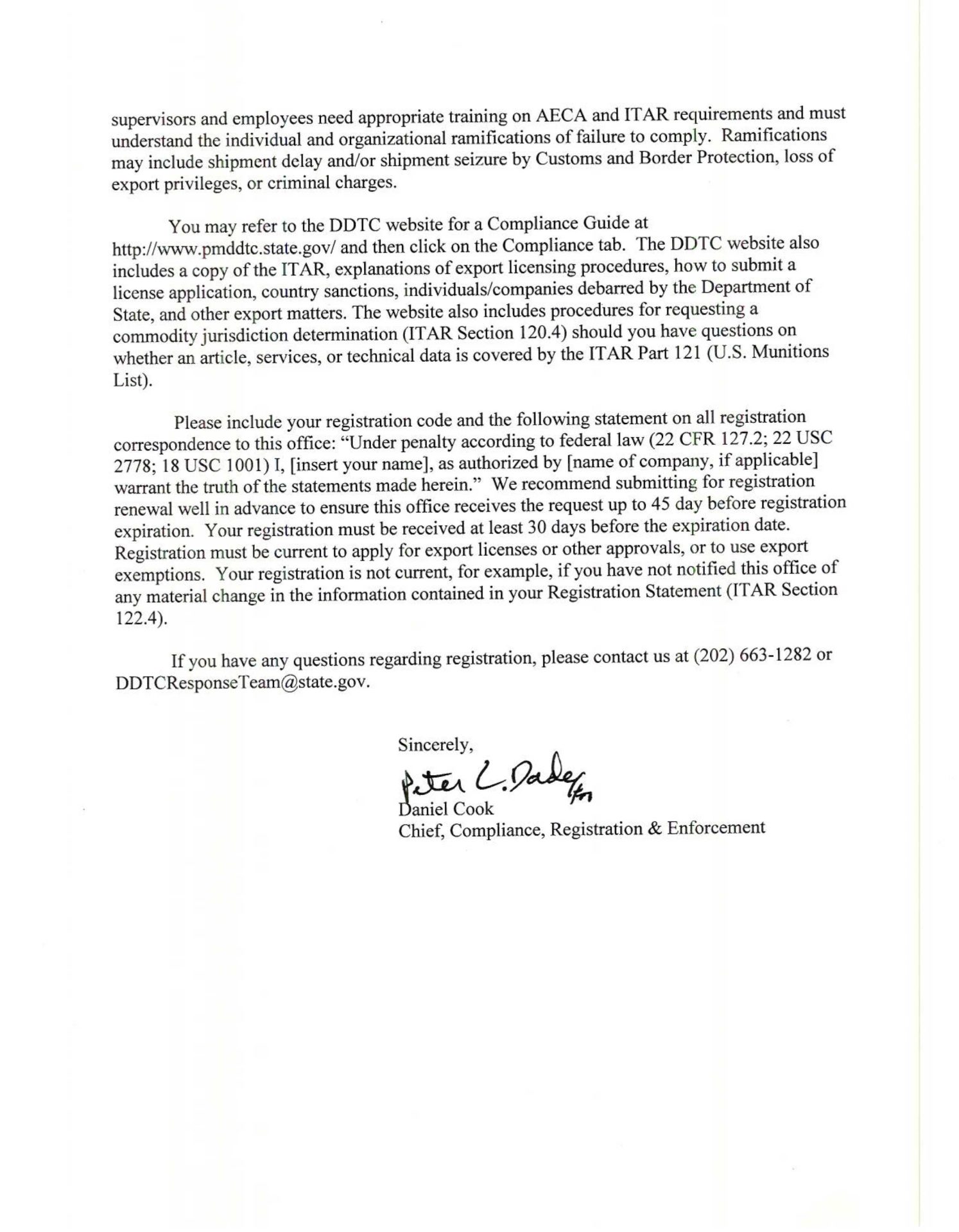

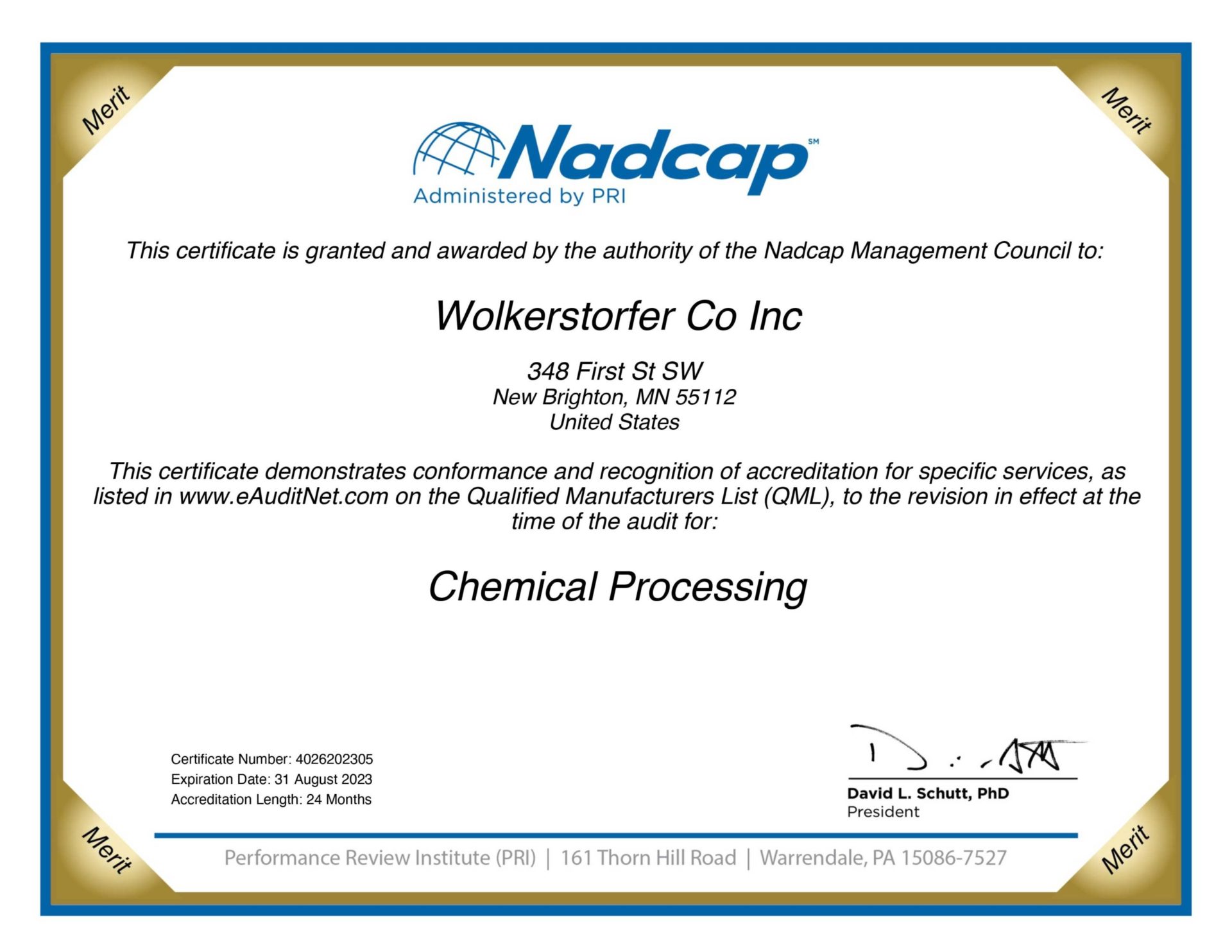

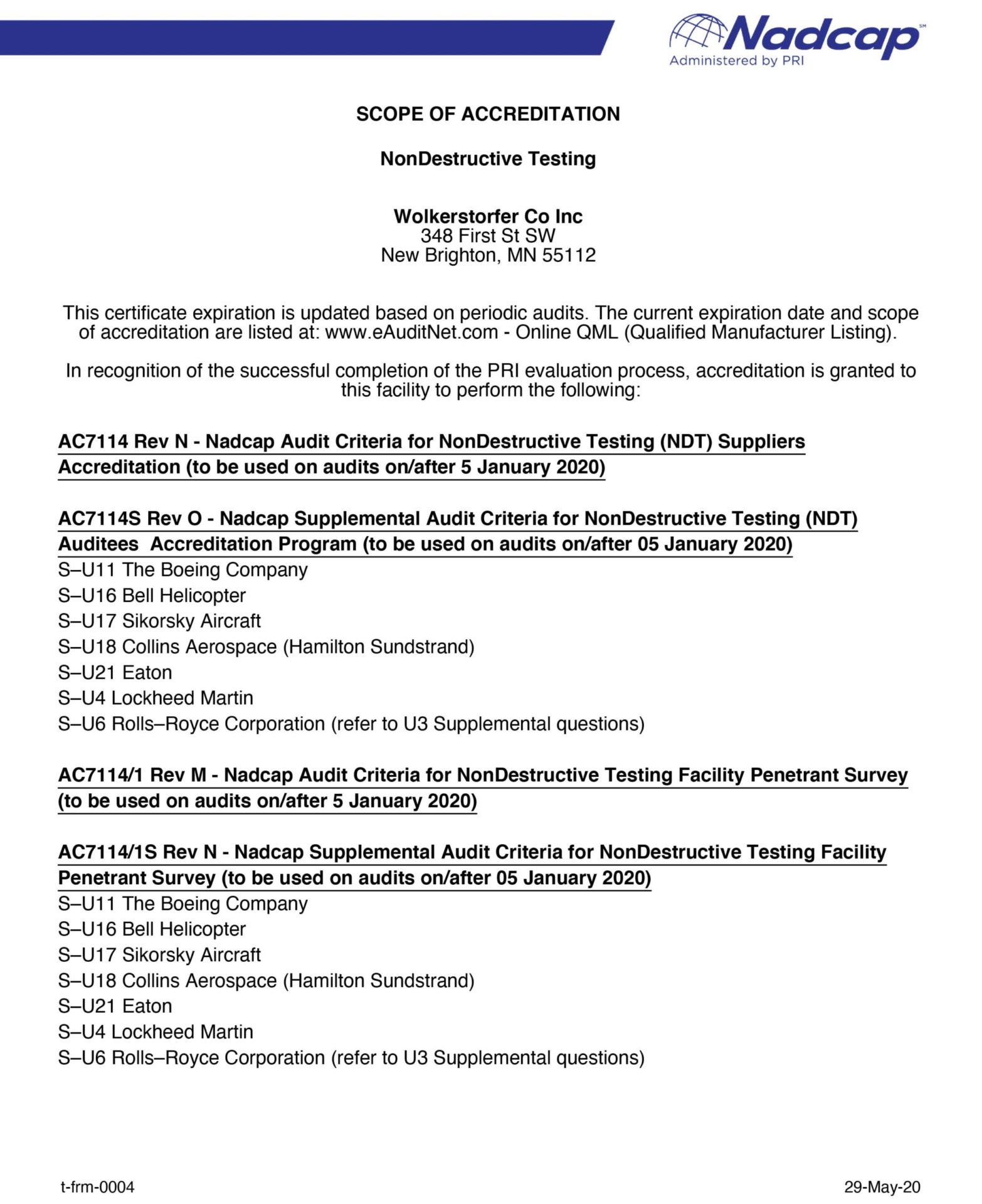

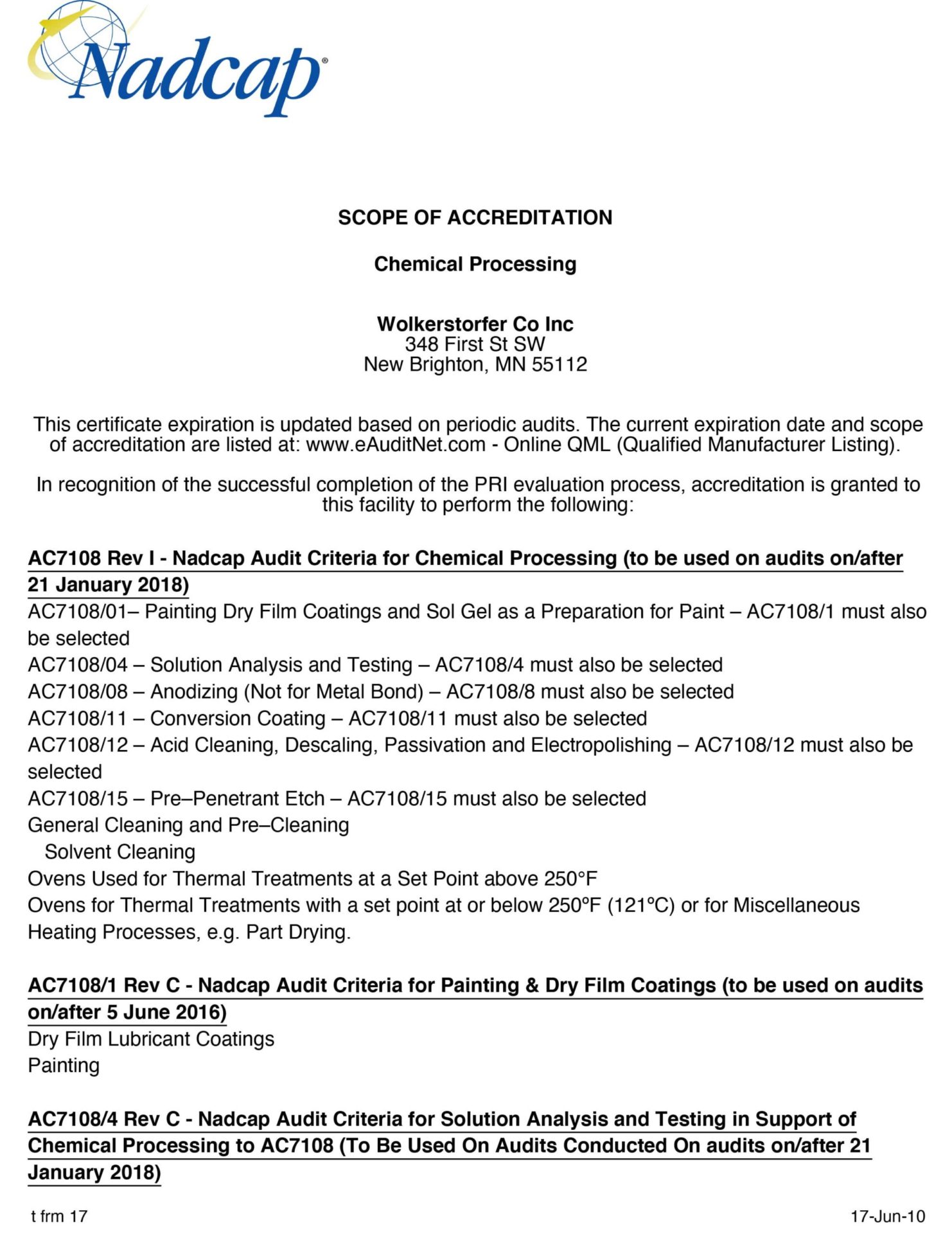

Wolkerstorfer Company, Incorporated has been in the finishing and testing business for over 129 years, providing superior service at a competitive price. Located just north of Minneapolis, in an 83,000 square foot building, Wolkerstorfer serves the aerospace, military, heavy industrial, and subsea markets. Nadcap and ITAR certified, Wolkerstorfer Company provides the personal service you need while meeting the strictest demands of companies like Boeing, Rolls Royce, Sikorsky, Honeywell and other OEM manufacturers.

Key Reasons to do business with Wolkerstorfer Company

- The ability to do non-destructive testing, plating, and painting under one roof saving our customers time and money.

- We have some of the largest metal finishing equipment in the Midwest.

- We are a well established, 4th generation company that is veteran and woman owned.

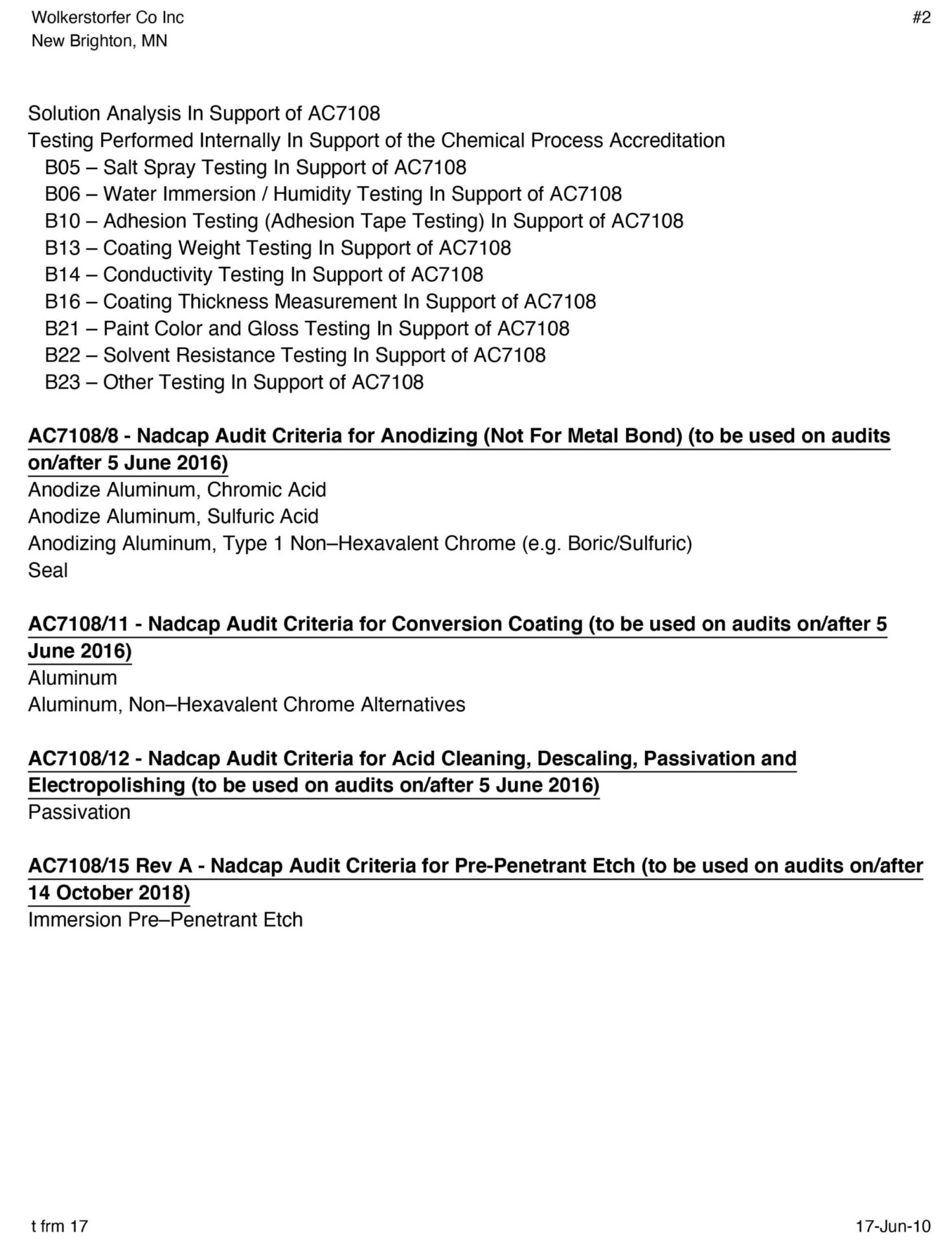

- We boast a “who’s who” of OEM certifications.

Value Added Services With WCI

The decision to work with a supplier is based on many things, including costs, logistics, and expertise. Some aspects are quantifiable, while others are more qualifiable. In the end, what matters most is quality and results. The way you get there, however, is certainly a factor worth understanding. With this in mind, allow us to build the case for why you should do business with a value added service provider. Wolkerstorfer stands out as a leading metal finishing company that provides reliable and consistent solutions when it comes to your Nadcap Painting, Plating, and Testing.

The Tangibles and Intangibles of Working with Wolkerstorfer Company

With a focus on the Nadcap metal finishing and testing requirements of the aerospace, military, and heavy commercial sectors, Wolkerstorfer Company boasts a number of accreditations from the most prestigious brands. The skilled management team at Wolkerstorfer Company has more than 250 years of combined experience and specializes in surface finishing, painting, non-destructive testing, and precision masking. Started in 1895 by the Wolkerstorfer family, the company is currently under the ownership and administration of its fourth generation. Service and attention to detail are priorities for this veteran and woman-owned company. That being said, there is so much more to this simple but professional midwest metal finishing company than meets the eye. Here are some of the top value added services you can expect from Wolkerstorfer.

Full Service Provider

The target market for Wolkerstorfer Company is the defense and aerospace industries. WCI offers several different services like Nadcap Anodize, Passivation, Fluorescent Penetrant Inspection, and Painting, specific to those niche markets. We have been audited and approved by the largest OEMs, like Raytheon, Honeywell, Rolls Royce, and Boeing, just to name a few. We can literally take your machined part and complete all the testing and finishing in one location. Wolkerstorfer Co. is the definition of a full-service metal finishing company. As experts in the aerospace and defense industries, we have learned what our clients expect, and what needs they may have beyond our standard offering. With this perspective, we engage in a vertical selling mindset, delivering a wide range of solutions for our clients. With this focused effort of marketing, sales, and product placement specific to the aerospace and defense industries, we are able to understand and provide end-to-end value added services that so many of our clients need.

Real Lead Time Management

Turnaround time is a key factor for any business, and this is no different for a metal finishing company in the defense and aerospace industries. Being able to reliably deliver fast turnaround on an order is necessary, and allows for more strategic planning. This is where Real Lead Time comes into play. A company’s Real Lead Time is the time between when the purchase order is issued to when the part is shipped to the customer. In Lean Manufacturing Terms: Real Lead Time = Value Added Time + Non-Value Added Time. Value Added Time is the time the part is changing physically during testing, plating, and painting. Non-Value Added Time is represented by shipping, staging, and packaging. This is why WCI being a full service provider is so important to our clients. You can reduce your Non-Value Added Time by eliminating the shipping of your product to multiple shops by using a centrally located full-service company — Wolkerstorfer Company.

Risk Mitigation

Risk Mitigation is the process of planning for disasters in order to lessen the impact or eliminate the possibility of disasters occurring altogether. Adherence to best practices are paramount for any metal finishing company, especially when they serve such vital industries. What impacts can be limited by sending the parts to a full-service facility? Here are a few of the most important:

Lead Time – When a single facility is handling the processing of your parts, there is no need for those parts to sit in the queue behind other orders at every stop. Once we receive an order it goes into a single queue where it flows smoothly through the entire process. This allows for a predictable completion cycle, reducing lead time and expediting the entire process.

Specification Restrictions – Every part has unique specifications that must be adhered to. If a full-service facility processes your parts, you can have confidence that they will be handled with a clear and congruent understanding of those specifications.

Handling/Shipping – When a part has to be shipped to multiple companies for testing and finishing, your risk of damage increases as it is exposed to being packed, unpacked, and handled at each location. A single value added service provider like Wolkerstorfer can ensure minimal handling and shipping, saving you time, money, and potential damage.

The Bottom Line

The possibility of damaging a part when it is being handled by multiple companies can result in a scrap piece that can be traced to a quantifiable cost. The potential of delays due to transit issues and varying lead times from company to company is more qualitative but is just as real. For these reasons, it is generally best to work with a full-service metal finishing company that offers value added services to deliver a complete experience. Wolkerstorfer cannot mitigate all the risks, but with our Nadcap quality system and trained staff, we feel we can put your company in a more manageable situation. This is perhaps the greatest of our value added services because it allows you to get dependable results quickly and efficiently.