This test involves a one hour immersion of a sample in distilled water, at room temperature, followed by a one hour drying cycle. This is then repeated for 12 cycles. If there is any evidence of staining or rust on the part the lot would be rejected.

This particular grade of stainless steel is susceptible to intergranular attack by nitric acid. In some of the older specifications it was recommended that this particular alloy not be processed through passivation.

Rockwell Collins Anodic Coatings Specification

Rockwell Collins Chemical Film Specification

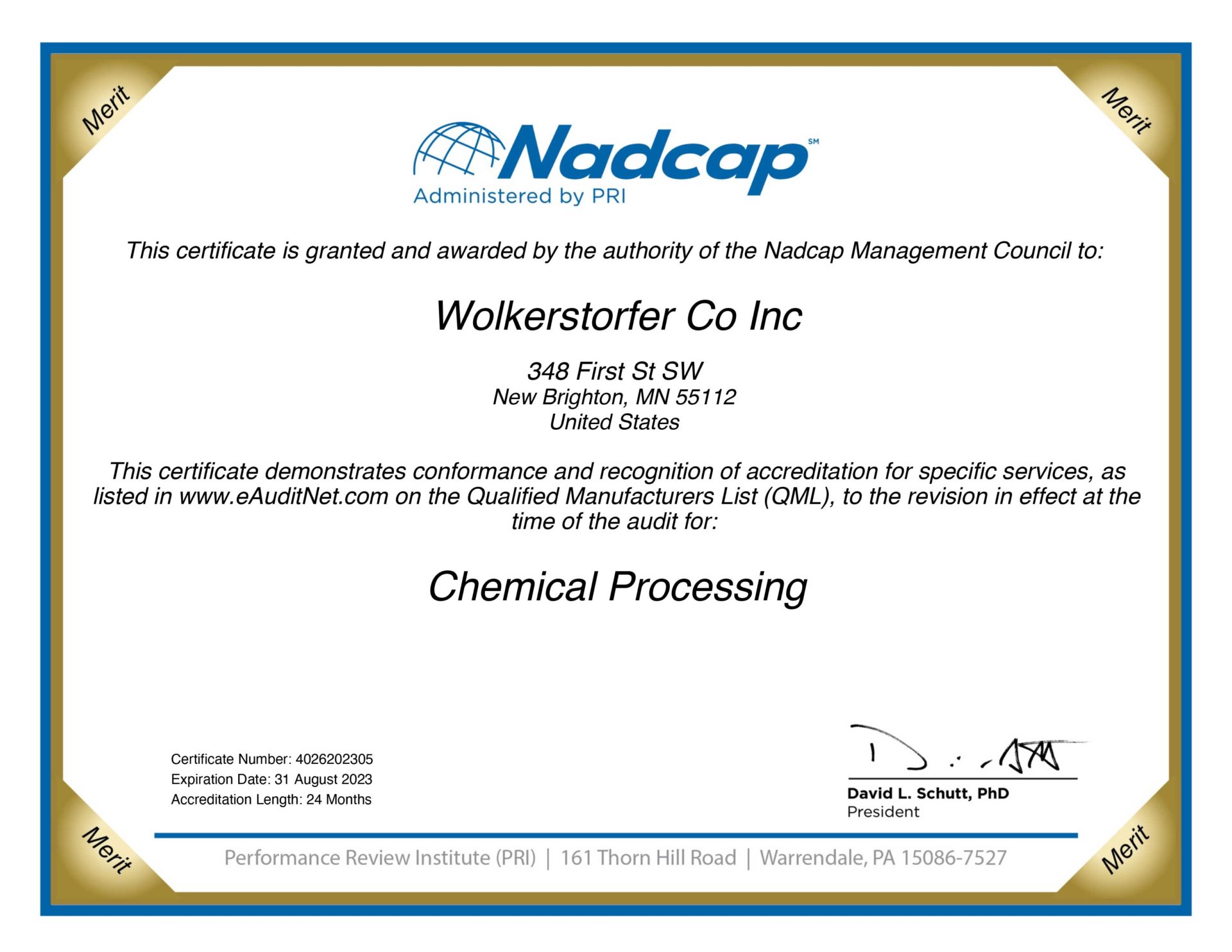

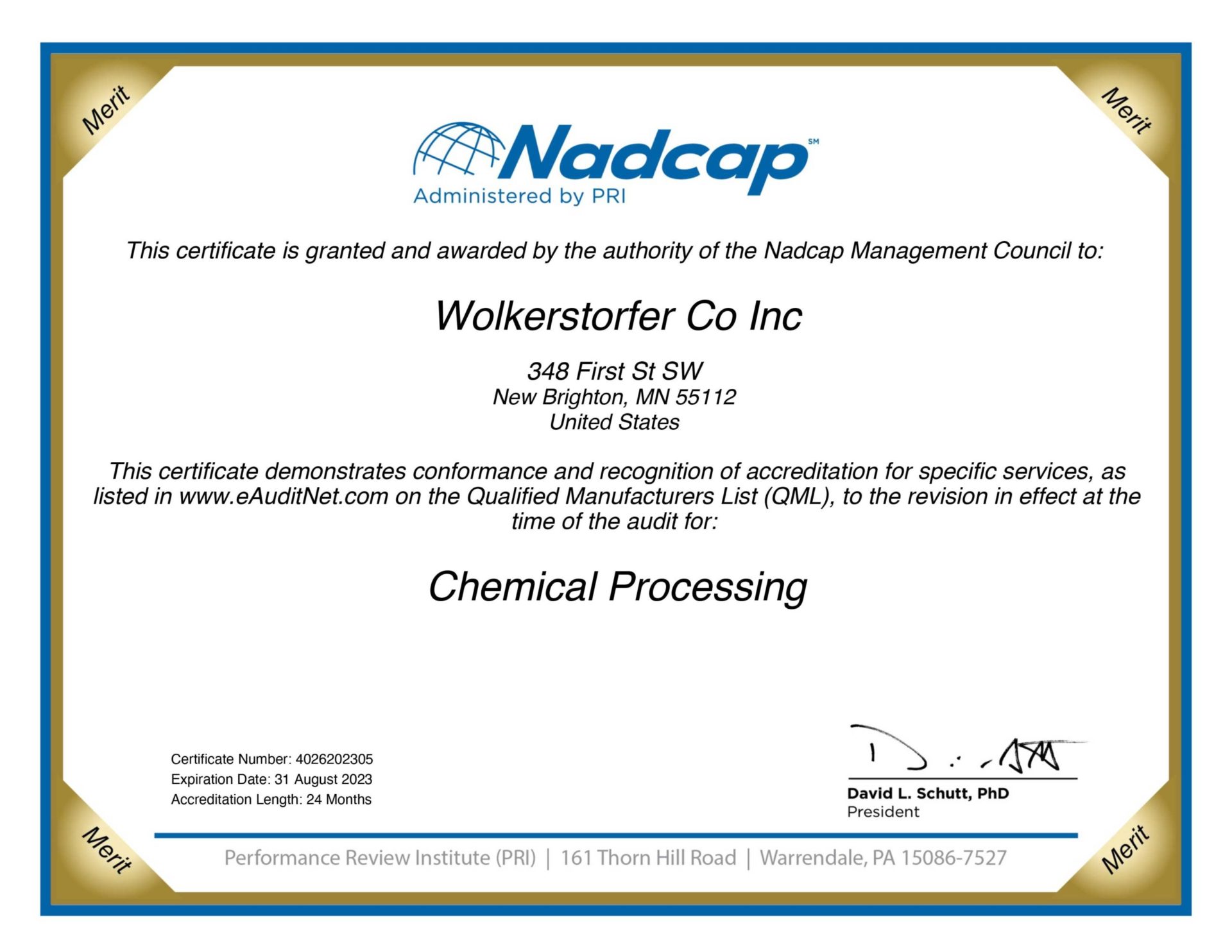

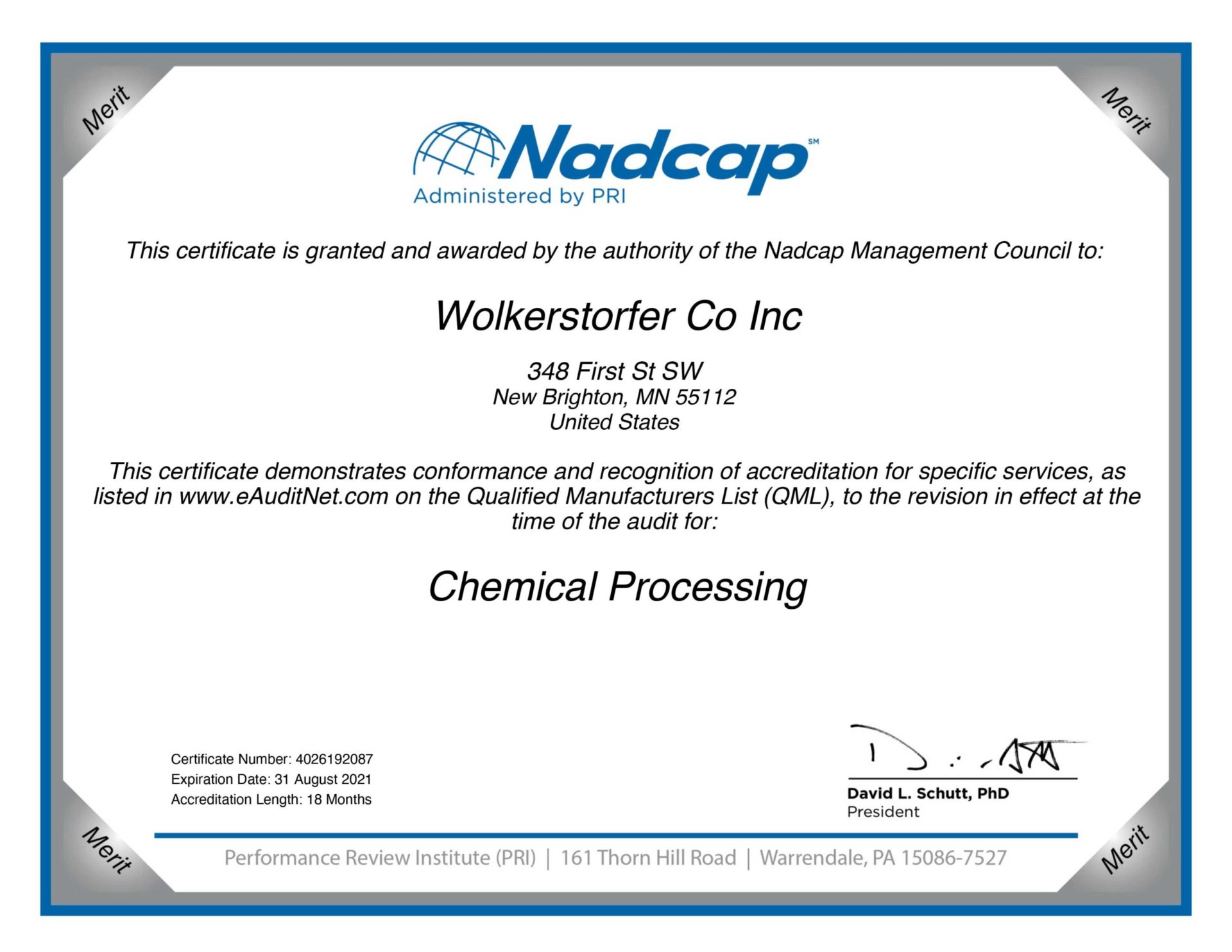

Derived from AS9001, this is the Nadcap Aerospace Quality System document. The Performance Review Institute created AC7004 for small businesses of under 100 employees to compete in the aerospace and defense industries. The AC7004 is based on the larger AS9100. You can see our most recent Nadcap certifications by clicking on this link.

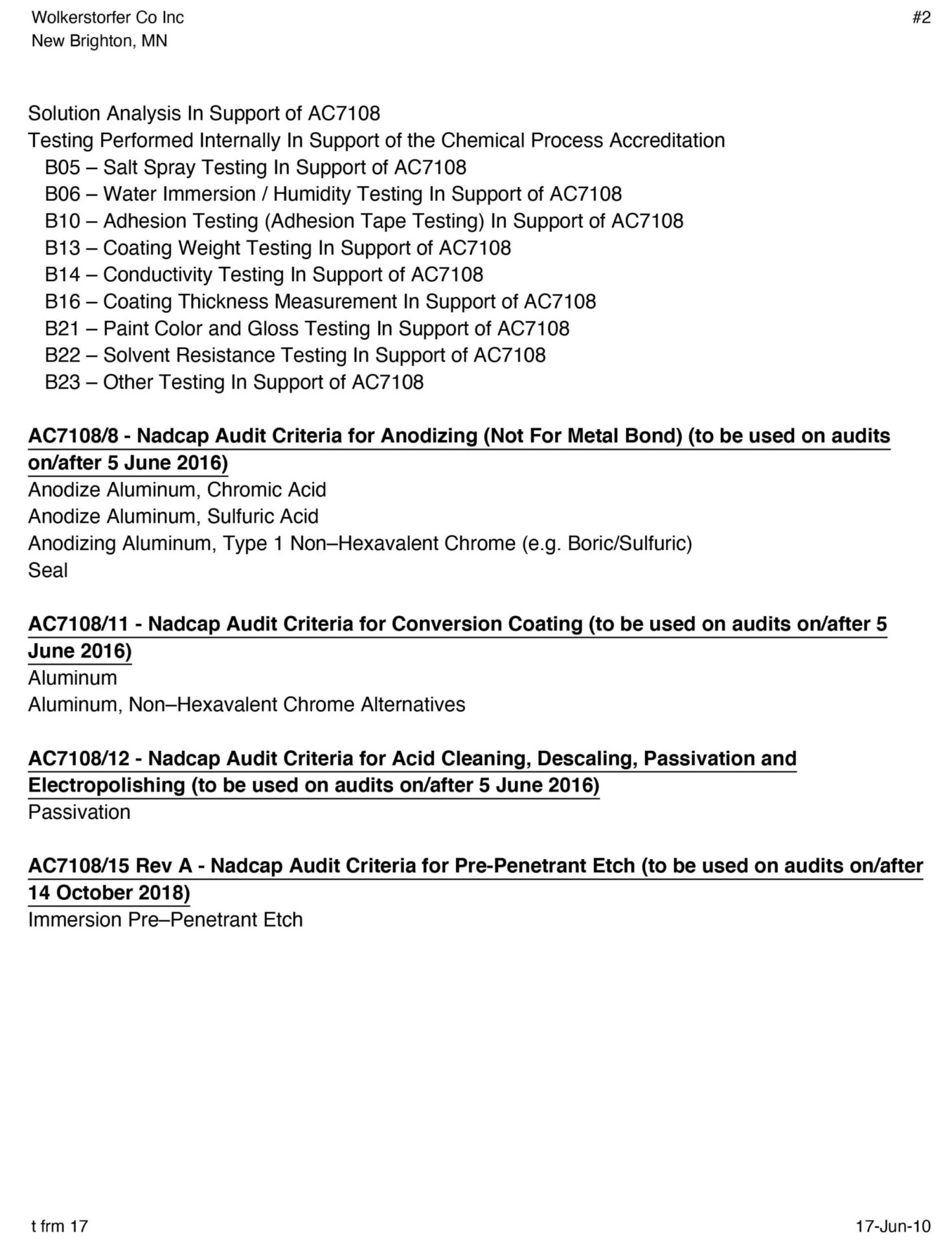

This is the overall Nadcap criteria for Chemical Processing. The subsets we are approved for are listed below:

- AC7108/1 Application of Paint, Dry Film Lubricants and Sol Gel

- AC7108/2 Etch Processes

- AC7108/4 Solution Analysis and Testing in Support of Chemical Processing

- AC7108/8 Anodizing

- AC7108/11 Conversion Coating

- AC7108/12 Acid Cleaning, Descaling, and Passivation

You can see our recent Nadcap certifications by clicking this link

The application of Paint, Dry Film Lubricants and Sol Gel

Acid Cleaning, Descaling, and Passivation

Solution Analysis and Testing in Support of Chemical Processing

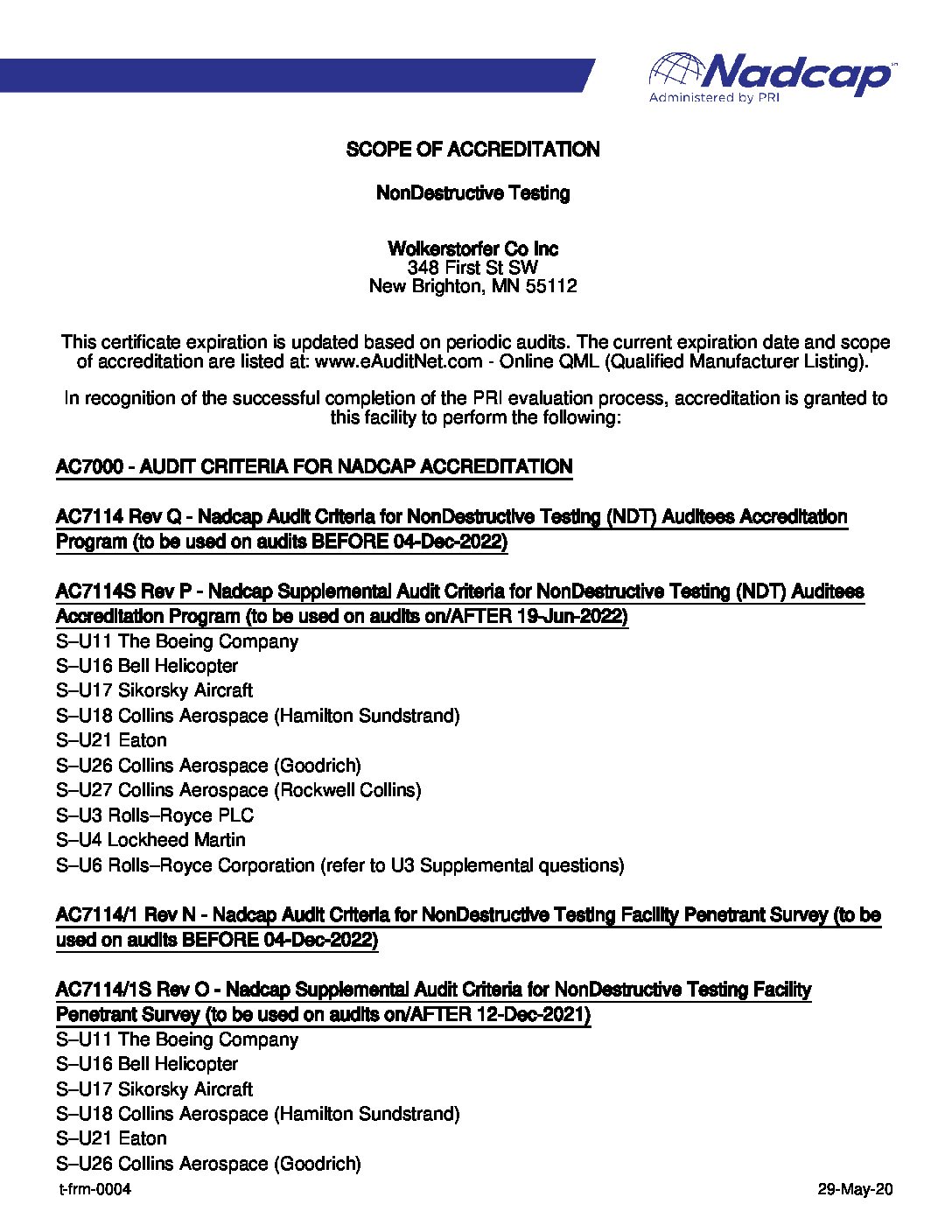

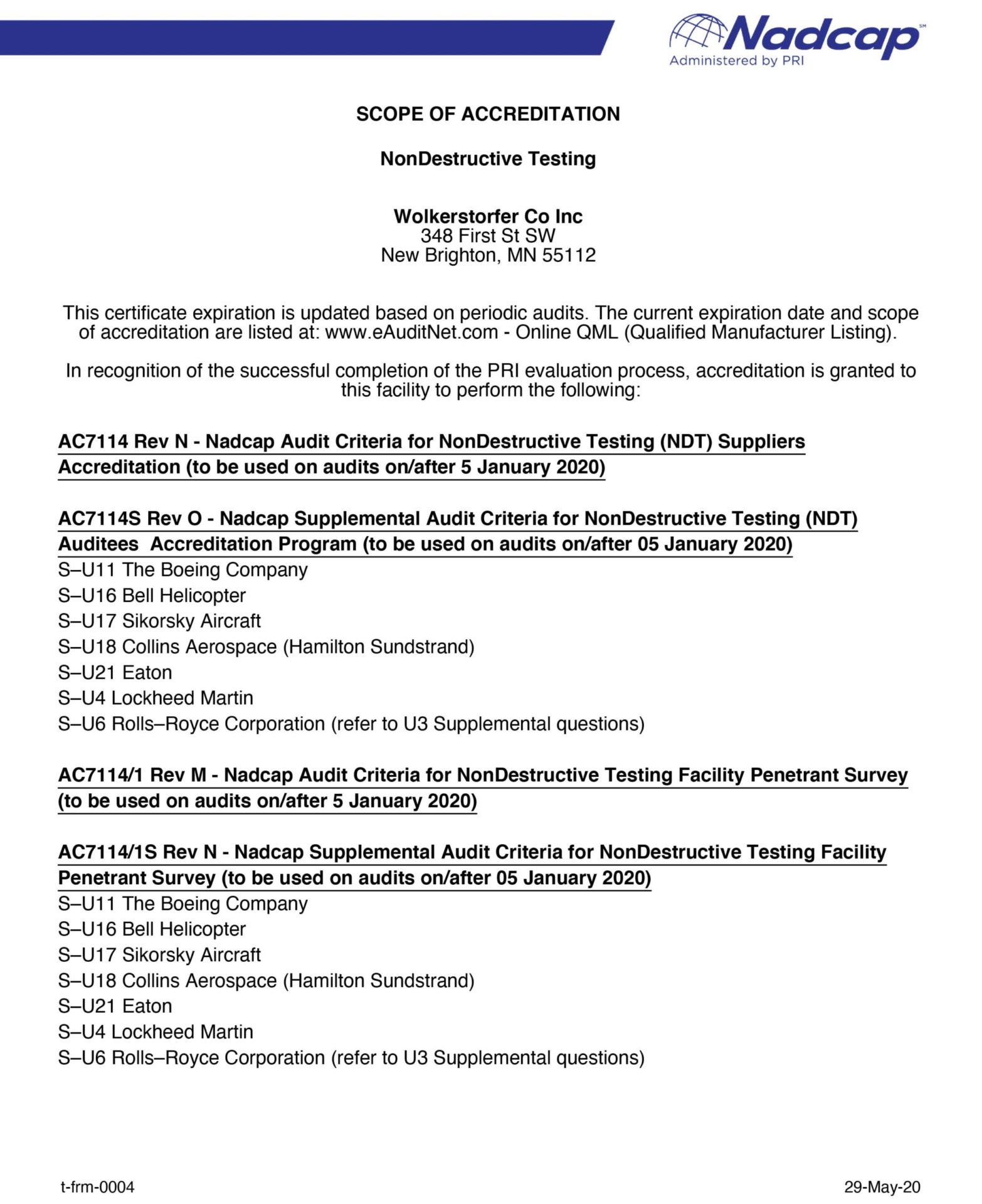

Nadcap - Non-Destructive Testing (NDT). The overall acceptance criteria from Nadcap involving non-destructive testing. You can see our most recent Nadcap certifications by clicking on this link.

A Henkel trade name for a family of various chromate conversion coatings.

The specification document AMS 2700 offers norms and recommendations for the passivation of stainless steel alloys. Stainless steel can be made more corrosion-resistant by using a chemical process called passivation, which cleans the metal's surface of impurities. The specifications, testing protocols, and processes for passivating stainless steel parts used in manufacturing and aerospace are outlined in AMS 2700.

This has been canceled and is superseded by AMS 2700

A coating, typically formed on aluminum, that provides an anodic aluminum oxide surface. This coating is non-conductive, provides corrosion protection and is also a reliable pretreatment for paint. The two types of anodize we offer are Sulfuric Anodize and Boric-Sulfuric Anodize.

Typical seals include hot water, nickel acetate and dilute chromic acid. Their purpose is to seal the anodize coating providing improved corrosion protection.

Solid Film Procurement Specification

This specification breaks out a number of different chemical systems, including nitric and citric acid solutions for the passivation of stainless steel alloys.

Details the parameters for conducting a salt spray test to measure the corrosion resistance of different coatings.

This test uses a prescribed tape to measure the adhesion of different paint systems on a scale of "0" (complete removal of the paint) to "5" (no peeling or loss of adhesion).

This specification sets the base line for the minimum requirements for liquid penetrant inspection.

A Boeing document detailing the procedures to conduct penetrant inspection, following the same parameters as ASTM E1417.

A catalog of different procedures for the preparation and coating of ferrous alloys.

Boeing’s patented anodize process developed to replace chromic acid anodize in aerospace. WCI is not only approved but also licensed to perform this process.

A Boeing controlled document detailing the process instructions for chemical conversion coatings or chem film.

Boeing Chemical and Solvent Resistant Finishes Specification

Boeing Protective Topcoat Specification

Boeing Urethane Compatible, Corrosion Resistant Primer Specification

Boeing Interior Decorative Urethane Paint System Specification

(BSAA) Meets MIL-A-8625, Type IC and BAC 5632. This Boeing patented and licensed anodize coating is a non-hexavalent chrome alternative to Chromic Acid Anodize. This is a RoHS compliant coating.

Chemical Agent Resistant Coatings were developed to protect military vehicles from chemical agents. This paint system is engineered to be easily decontaminated after exposure to chemical and biological warfare agents, and also protects against radioactivity.

(Chem Film) Meets MIL-DTL-5541, Type I (hexavalent) and II (trivalent). This is a protective chromic conversion film over aluminum that is conductive, enhances corrosion protection and is a good pretreatment for paint.

(CAA) Meets MIL-A-8625, Type I and Type IB. This coating is in the process of being phased out but is still active in some aerospace and defense applications. The coating contains hexavalent chrome meaning it is NOT RoHS compliant. Wolkerstorfer Co, Inc. no longer offers this coating.

Meets AMS 2700, ASTM A967, QQ-P-35, AMS QQ-P-35. This is one form of passivating stainless steel. There are various bath concentrations and temperatures that can be used, typically determined by the alloy of the stainless steel.

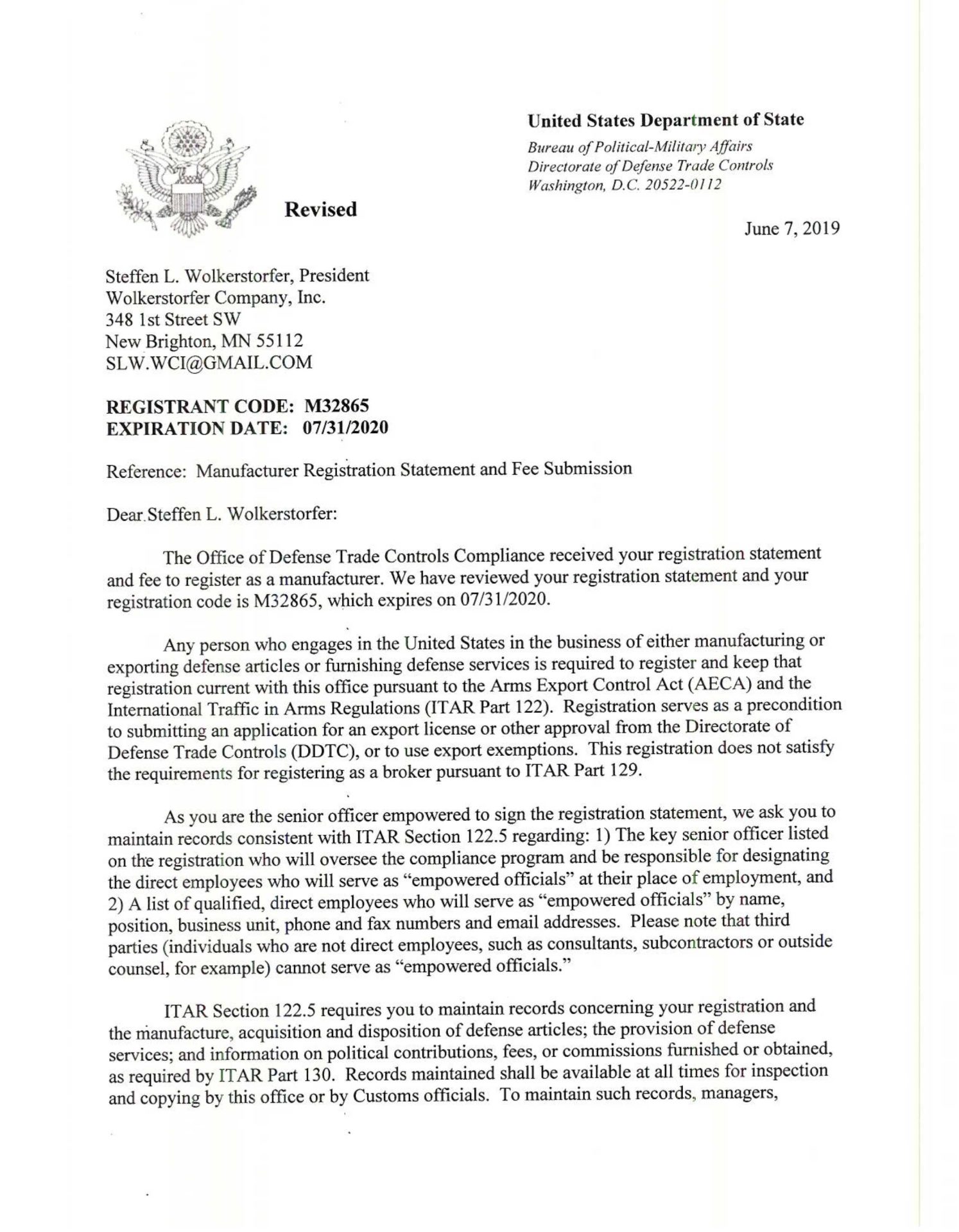

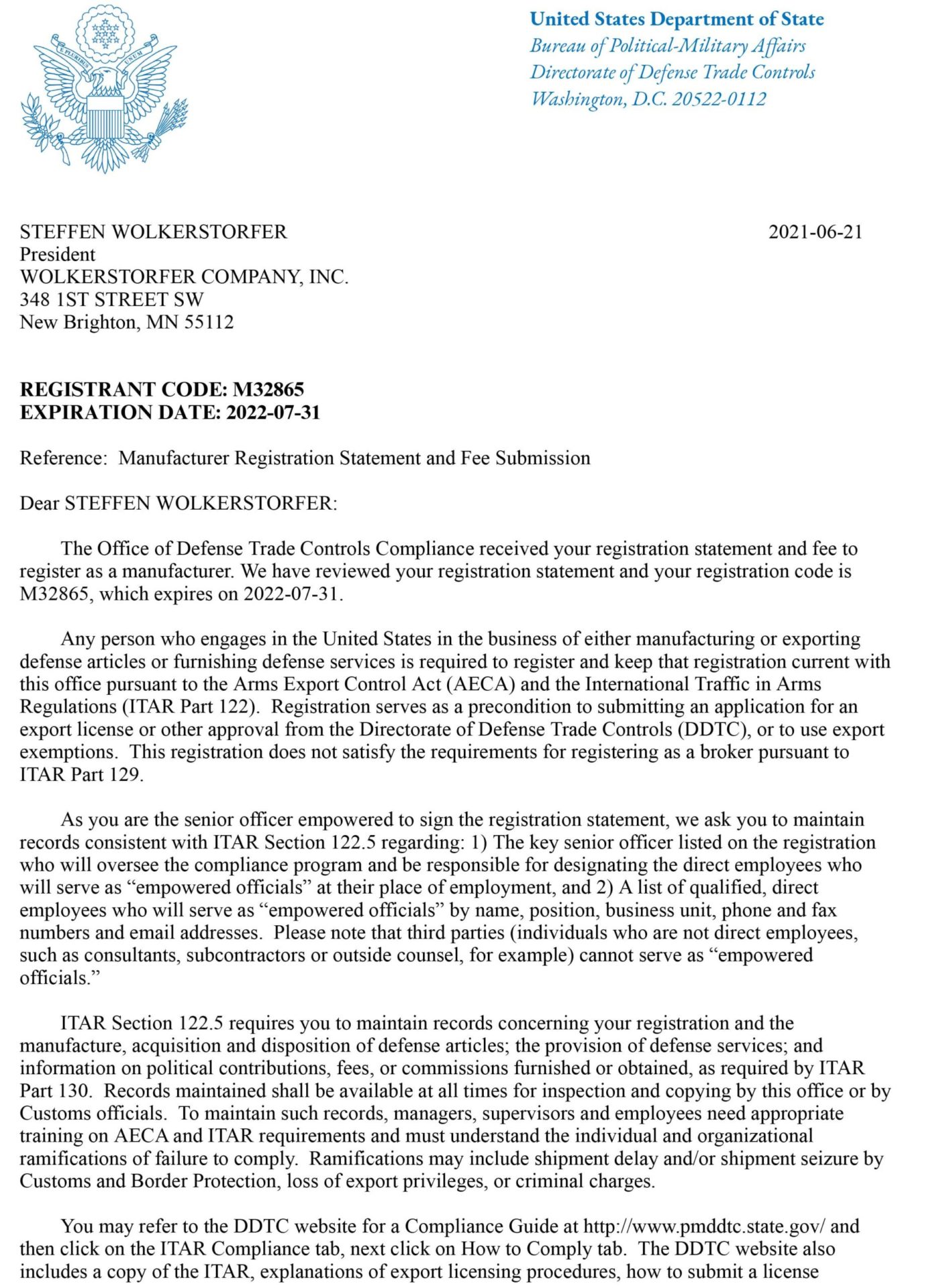

The Cybersecurity Maturity Model Certification is a law passed by Congress to put controls and restrictions on how companies are allowed to share information identified as ITAR controlled documents. It requires companies to establish “practices” for the control between companies as well as how those documents are controlled within one’s own business. Ultimately in order to perform work directly or indirectly for the DoD a business will have to be third partied certified, similar to Nadcap or ISO requirements.

Certain coatings are qualified by physically weighing deposit as opposed to measuring the thickness. Type I and II anodize and phosphate coatings fall in this category. Although there is some actual buildup of these coatings the industry uses the weight as the acceptance criteria for validating these coatings.

This test is referenced in ASTM A967 as a way of detecting free iron on the surface of certain grades of stainless steel. The presence of copper on the surface of the part post-test indicates the presence of free iron, and is cause for rejection.

Controlled Unclassified Information

DFARS stands for Defense Federal Acquisition Regulation Supplement. It is a set of regulations and guidelines issued by the U.S. Department of Defense (DoD) to supplement the Federal Acquisition Regulation Supplement (FARS). DFARS contains specific requirements and clauses that government contractors and subcontractors must follow when conducting business with the DoD. These regulations cover various aspects of procurement, contract administration, and compliance, with a focus on ensuring the security and integrity of defense-related acquisitions.

Dry Film Lubricants (DFL), also known as Solid Film Lubricants (SFL), provide lubrication in areas where wet lubricants are not practical. Dry Films are typically made up of formulas containing molybdenum disulfide, graphite, or Teflon™. Some Dry Films also provide excellent corrosion protection.

End-of Life Vehicles (ELV) is a European initiated program promoting the re-use or recycling of automotive parts, ultimately reducing the impact to landfills.

When electromagnetic waves interfere with the operation of electronic devices, communication systems, or other sensitive equipment, it is referred to as electromagnetic interference, or EMI. EMI can interfere with signals, reduce performance, and cause faults in devices that are impacted.

The Federal Acquisition Regulation System, or FARS, is a collection of regulations that the federal government of the United States of America enacted to control the procurement and acquisition procedures for federal agencies. A uniform framework for government contracts known as FARS covers a number of topics, including formation, administration, price, and compliance. Its goal is to guarantee government procurement procedures' impartiality, consistency, and transparency.

In the United States, the regulatory agency known as the Federal Communications Commission (FCC) is in charge of monitoring and controlling a number of areas related to radio frequency usage, broadcasting, and telecommunications. Its goals are to safeguard consumers, maintain fair competition, and oversee the licensing and distribution of wireless spectrum in order to minimize interference and encourage effective use of available communication resources.

Also called Liquid Penetrant Inspection or FPI. This test system involves the use of penetrating solutions and subsequent developers to expose surface imperfections to the naked eye under ultra-violet light.

A friable coating is designed to fracture on impact or in a “load on load” basis. Phosphates’ friable structure provide a sacrificial coating that facilitate in the initial break-in of assemblies that have metal to metal contact.

Meets MIL-DTL-5541, Type I. This conductive conversion coating contains hexavalent chrome which is being phased out due to environmental and health reasons. This is a NON-compliant RoHS coating.

A trade name for a bath concentrate used in the make-up of chromate conversion solution.

International Traffic in Arms Regulation is a U.S. regulatory regime designed to restrict the export of defense and military related technologies to safeguard U.S. national security.

Meets MIL-DTL-16232, Type M. It is used as a break-in lubricant or as a pretreatment for other coatings like paint.

Superseded by MIL-PRF-8625 Specification

Coating Compound, Metal Pretreatment, Resin-Acid Specification

Phosphate Coating, Heavy, Manganese or Zinc Base Specification

Primer Coating, Epoxy, Water-Based, Lead and Chrome Free Specification

Coating, Aliphatic Polyurethane, Single Component, CARC Specification

Chemical Agent Resistant Coating (CARC) System Specification

The most popular of the specifications for Chemical Conversion Coatings for aluminum. There are two “Types” and two “Classes” that can be designated. Type I has hexavalent chrome in it and Type II has trivalent chrome. The Class 1A is designed for maximum corrosion protection while the Class 3 is called out in applications where low electrical resistance is the primary function and/or RoHS compliance is required.

Camouflage Coating, Chemical Agent Resistant Specification

Chemical Conversion Material for Aluminum Specification

Lubricant, Solid Film, Air-Cured/ NATO Code S-749 Specification

Coating, Epoxy, High Solids Specification

Primer Coatings: Epoxy, High Solids Specification

Coatings meeting this specification will provide excellent lubricity and corrosion protection. This is one of the more common heat cured Dry Film Lubricant specifications that is used in the field.

Lubricant, Solid Film, Air-Cured Specification

Primer, Epoxy Coating, Lead and Chromate Free Specification

Lubricant, Solid Film, Extreme Environment/ NATO Code S-1737 Specification

Topcoat, Aircraft and Support Equipment Specification

Primer Coatings, Epoxy, Waterborne Specification

MIL-PRF-8625 is a military specification that outlines the requirements and standards for the anodizing of aluminum and aluminum alloys. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, improving its corrosion resistance and durability. MIL-PRF-8625 lists the different types, classes, and performance standards for anodizing processes used in aerospace and military applications. This is done to make sure that the quality and performance of anodized aluminum parts are always the same.

This specification provides the needed criteria for what visual imperfections are acceptable or not during the inspection process.

Nadcap is the National Aerospace and Defense Contractors Accreditation Program. Nadcap is a global cooperative accreditation program for aerospace engineering, defense, and related industries. This quality initiative is designed to provide superior performance and standardization across all platforms.

The National Institute of Standards and Technology published 800-171 to establish guidelines to handle “Controlled Unclassified Information or CUI among other security protocols.

Meets AMS 2700, ASTM A967, QQ-P-35, AMS QQ-P-35. This is one form of passivating stainless steel. There are various bath concentrations and temperatures that can be used, typically determined by the alloy of the stainless steel.

There are two types of testing for materials: Destructive which involves actually destroying a part in order to test its physical characteristics and NonDestructive which allows a person to test a component in such a way as to allow it to still be used in the field.

Paint is any pigmented liquid that after application to most substrates turns to a thin solid film. It is most commonly used to provide corrosion protection, color, or provide texture to objects.

An immersion process designed to remove free iron and sulfur from the surface of stainless steel in order to promote longer service life and protection from corrosion. This is NOT a pickle or descaling operation for the removal of heat treat tint or weld scale.

Phosphate coatings consist of a crystalline conversion coating on steel substrates for use as a pretreatment for other coatings or as a break-in lubricant. Phosphates are quantified by coating weight not thickness due to their fragile grain structure.

Hamilton Sundstrand Liquid Penetrant Inspection Specification

During the pre-penetrant process an etch is often used to remove any soft metal smears or residual trace metals left behind from the manufacturing process allowing the indications to be more easily identified. In the case of aluminum, depending on the specification the amount of metal removal is in the .0002” to .0004” range per side.

The function of the primer is to increase the bond strength of the subsequent topcoat to the surface, increases paint durability, and/or provide an extra layer of corrosion protection.

Stainless Steel Passivation Specification

REACH is the key chemical control regulation in the European Union. The acronym REACH stands for Registration, Evaluation, Authorization and Restriction of Chemicals manufactured in or imported into the European Union.

When different electronic devices create radio frequency signals that interfere with the operation of other nearby devices or systems, this is known as radio frequency interference (RFI), an undesired and disruptive kind of electromagnetic interference. In wireless and electronic systems, RFI can result in decreased signal quality, hiccups in communication, and degraded performance.

The Restriction of Hazardous Substances Directive adopted in 2003 by the European Union (EU) restricts the use of ten (10) hazardous chemicals in the manufacturing of various types of electronic components. This has been extended to all areas of manufacturing recently. This far-reaching directive basically states that if any of these chemicals are used in the manufacturing of a component it will not be allowed in the EU.

Lubricant, Solid Film Specification

This SAE specification establishes the basic instructions to apply dry film lubricants at a variety of thermal curing temperatures.

Also called Salt Spray Testing, is described in ASTM B117. The test provides a controlled corrosive environment which is used to generate resistance information for metals and coated metals exposed in the test chamber.

A brand of aviation hydraulic fluid called Skydrol is used in the hydraulic systems of aircraft. Because of its well-known ability to withstand fire, it is essential to maintaining aircraft safety. Skydrol facilitates power transmission in an aircraft's hydraulic systems, such as those for the landing gear, brakes, and flight control surfaces. Its fire-resistant qualities increase overall aviation safety by lowering the possibility that hydraulic fluid will ignite in the event of an aircraft fire.

(SAA) Meets MIL-A-8625, Type II and Type IIB. This is the most frequently designated anodize system and is a RoHS compliant coating.

A DuPont trade name for Polytetrafluoroethylene. This synthetic resin provides excellent lubricity under light loads.

The topcoat provides the color and the primary function for the coating. Corrosion and wear resistance would be two examples of the function required of this coating.

Meets MIL-DTL-5541, Type II. This conductive conversion coating IS RoHS, ELV, and WEEE compliant. The trivalent system is gaining in popularity.

Type I, Zinc Phosphate is very commonly called out for commercial and government contracts. This coarse grain crystal coating has a coating weight of 400 mg/ ft2 on average.

A wash primer is an organic coating typically containing phosphoric acid and zinc chromate. The acid provides a slight etch on the part while the zinc provides modest corrosion resistance. This is often followed by a secondary primer and top coat system.

Waste from Electrical and Electronic Equipment, or WEEE, was also developed by the European Union. Directed as a recycling endeavor this has a global impact for businesses that choose to do business in Europe or affiliated countries.

Meets TT-C-490, Type I. It is used to provide modest corrosion protection or as a pretreatment for other coatings like paint.