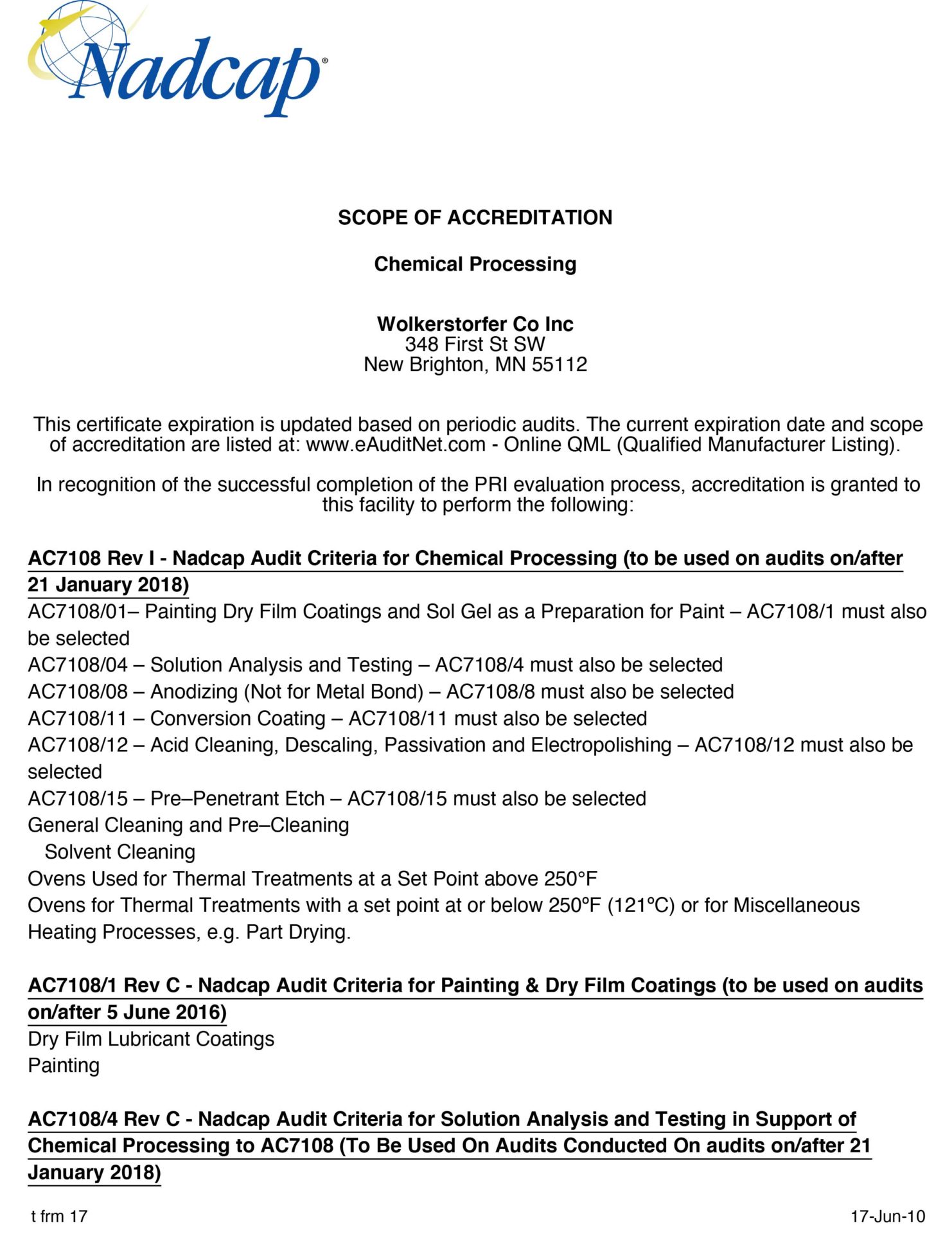

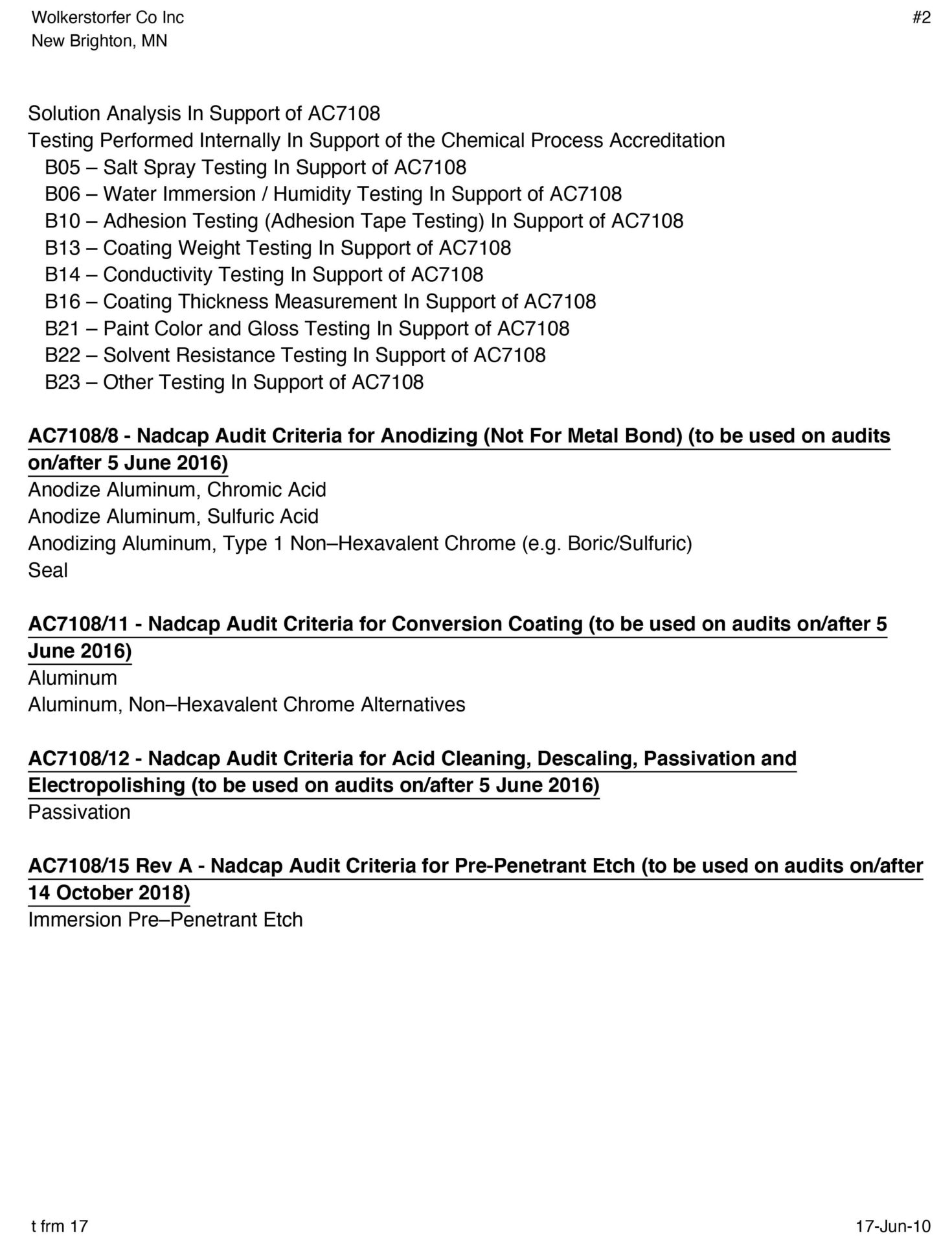

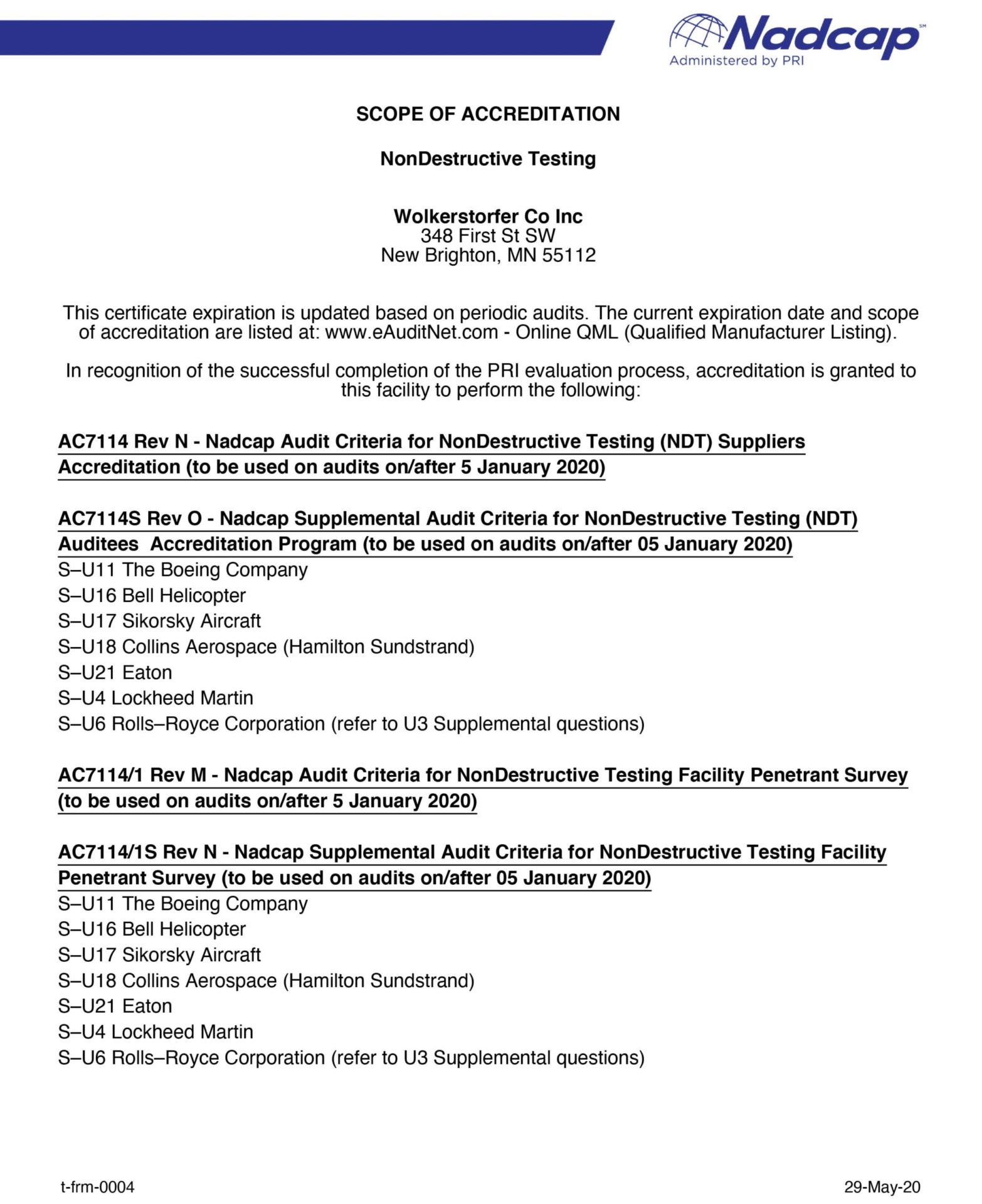

Nadcap Process Support Testing

In order to be in full compliance for our coatings, we are required by various specifications to perform various forms of destructive and non-destructive process support testing to validate that our processes are in control. Process support testing may involve wet analysis and chemical titration to make sure our chemistries are within the manufacturers’ parameters. Some of these tests may occur post processing to comply with the coating requirements depending on the Prime / OEM. Testing is required to maintain our Nadcap certifications and these tests meet a variety of federal and aerospace specifications. We have listed a few of the processes we do to support our production and quality systems

ASTM B117 (Salt Spray Testing)

Salt spray testing is a commonly accepted accelerated test to measure the corrosion resistance of various coating systems. Testing is performed on panels that are processed with the job, or on actual parts when required. All our salt spray testing is performed in house, versus using an outside laboratory, saving your company time and money.

ASTM D 3359 (Paint Adhesion Testing: Tape)

Federal Test Method Standard 141

When called out on the purchase order we are able to perform paint adhesion and chemical resistance testing in accordance with ASTM D 3359 and Federal Test Method Standard 141. Examples of this testing include dry tape test, paint adhesion, water resistance, and cross hatch scribe. Testing is typically performed on test panels provided by the customer to avoid damage to the actual parts themselves.

ASTM A 967 (Copper Sulfate Testing)

Copper sulfate testing in accordance with ASTM A 967 is an inexpensive nondestructive method for the detection of free iron on the surface of a part. This type of testing is typically required on 300 series stainless steel alloys, after passivation.

MIL-DTL-81706 (Contact Electrical Resistance Testing)

This rigorous test requires several steps, and the resistance measurements are on the low end of the microohm psi scale. This is required when the resistance of the chemical conversion coating per MIL-DTL-5541, either Type I or II, is highly critical. Our aerospace and defense customers will often require this test on a monthly or per-lot basis. Ten readings are taken on a controlled test panel after chem film at 200 psi downward force. The readings cannot be greater than 5,000 microohms psi as applied and 10,000 microohms psi after 168 hours of salt spray testing per ASTM B117. This test must be specifically referenced on the purchase order in order to maintain strict compliance. In order to support this high-value requirement, we have invested in our own in-house test equipment, which helps expedite the process.