Primer Coatings, Epoxy, Waterborne Specification

Archives

MIL-PRF-53022

Primer, Epoxy Coating, Lead and Chromate Free Specification

AC7108/1

The application of Paint, Dry Film Lubricants and Sol Gel

RoHS

The Restriction of Hazardous Substances Directive adopted in 2003 by the European Union (EU) restricts the use of ten (10) hazardous chemicals in the manufacturing of various types of electronic components. This has been extended to all areas of manufacturing recently. This far-reaching directive basically states that if any of these chemicals are used in the manufacturing of a component it will not be allowed in the EU.

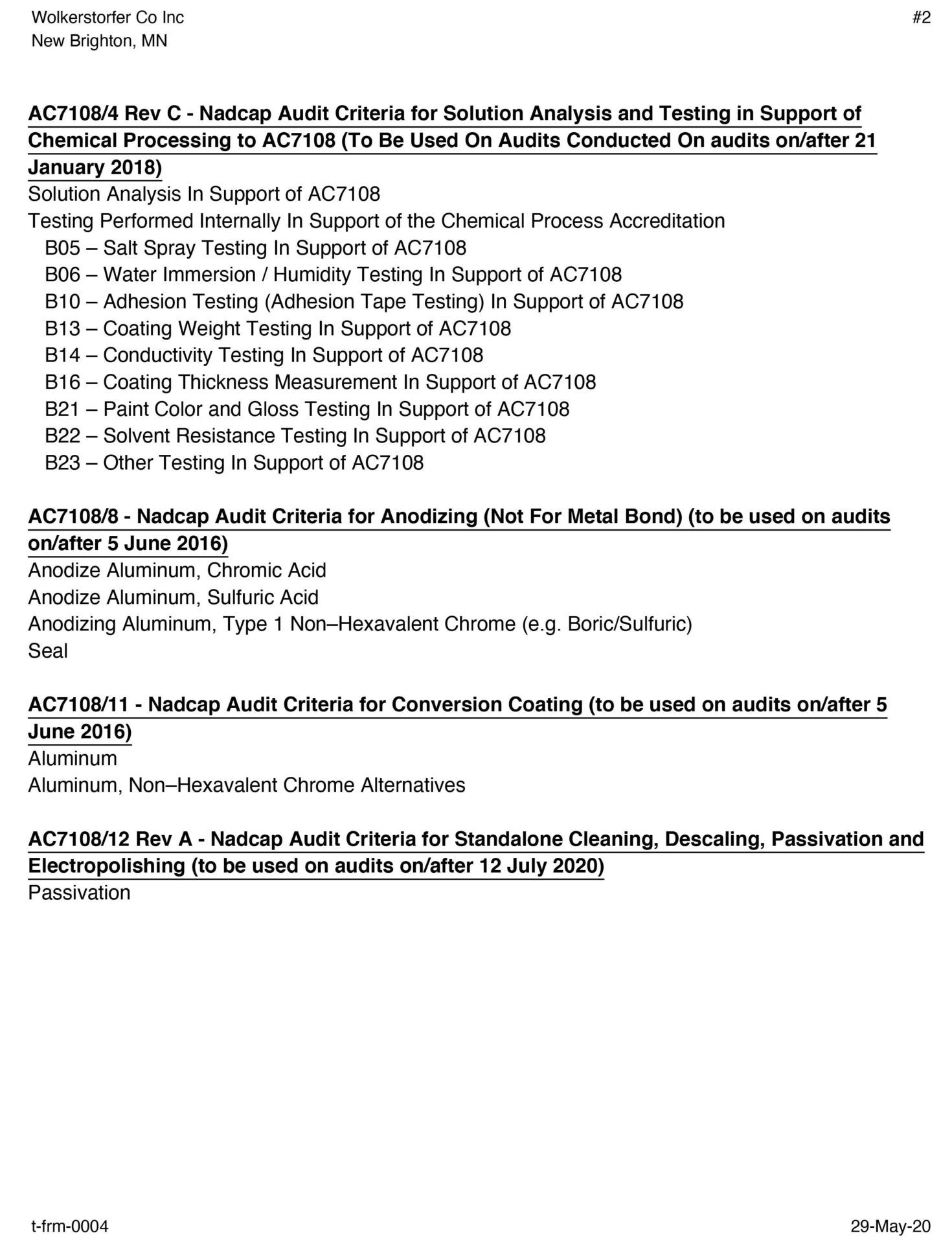

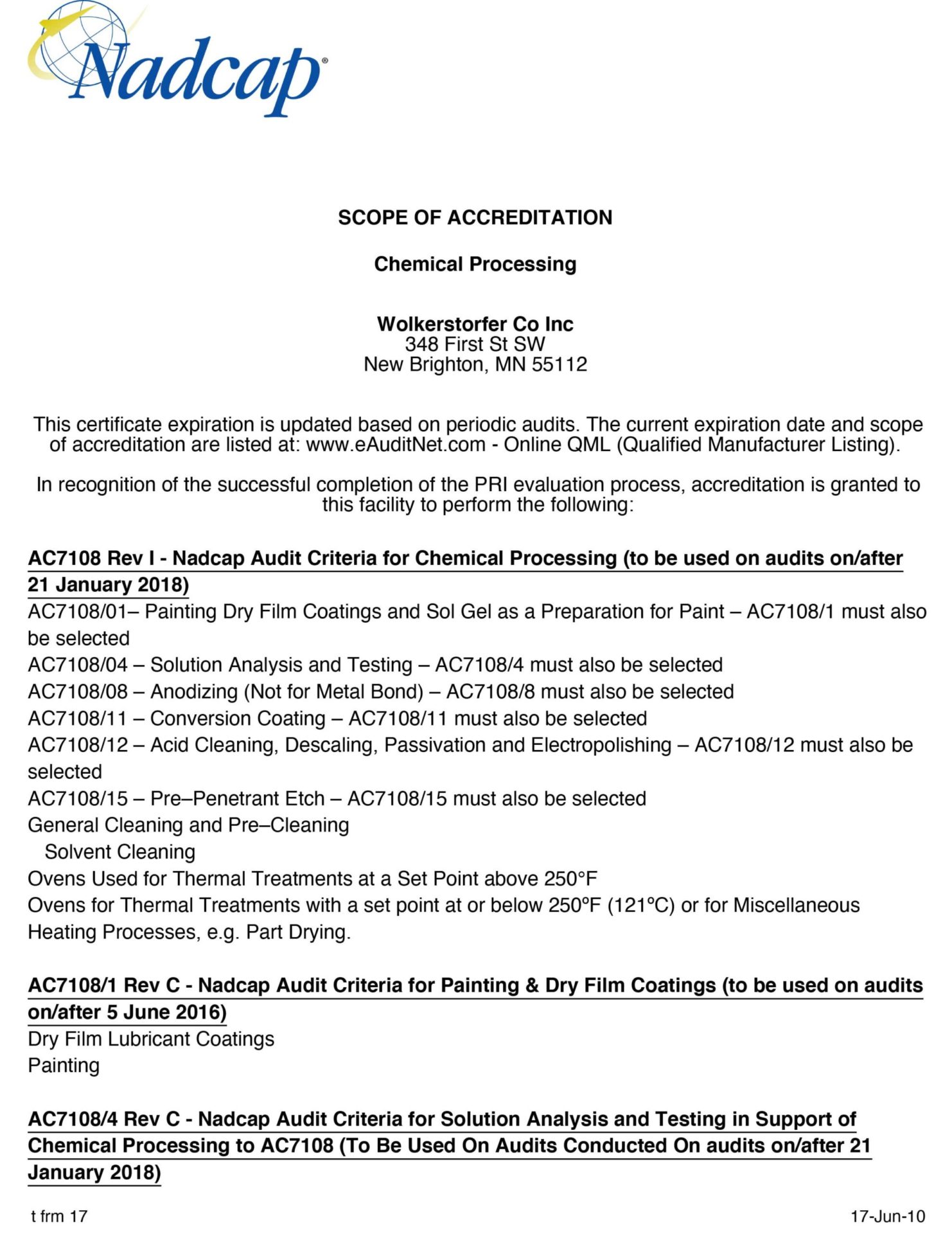

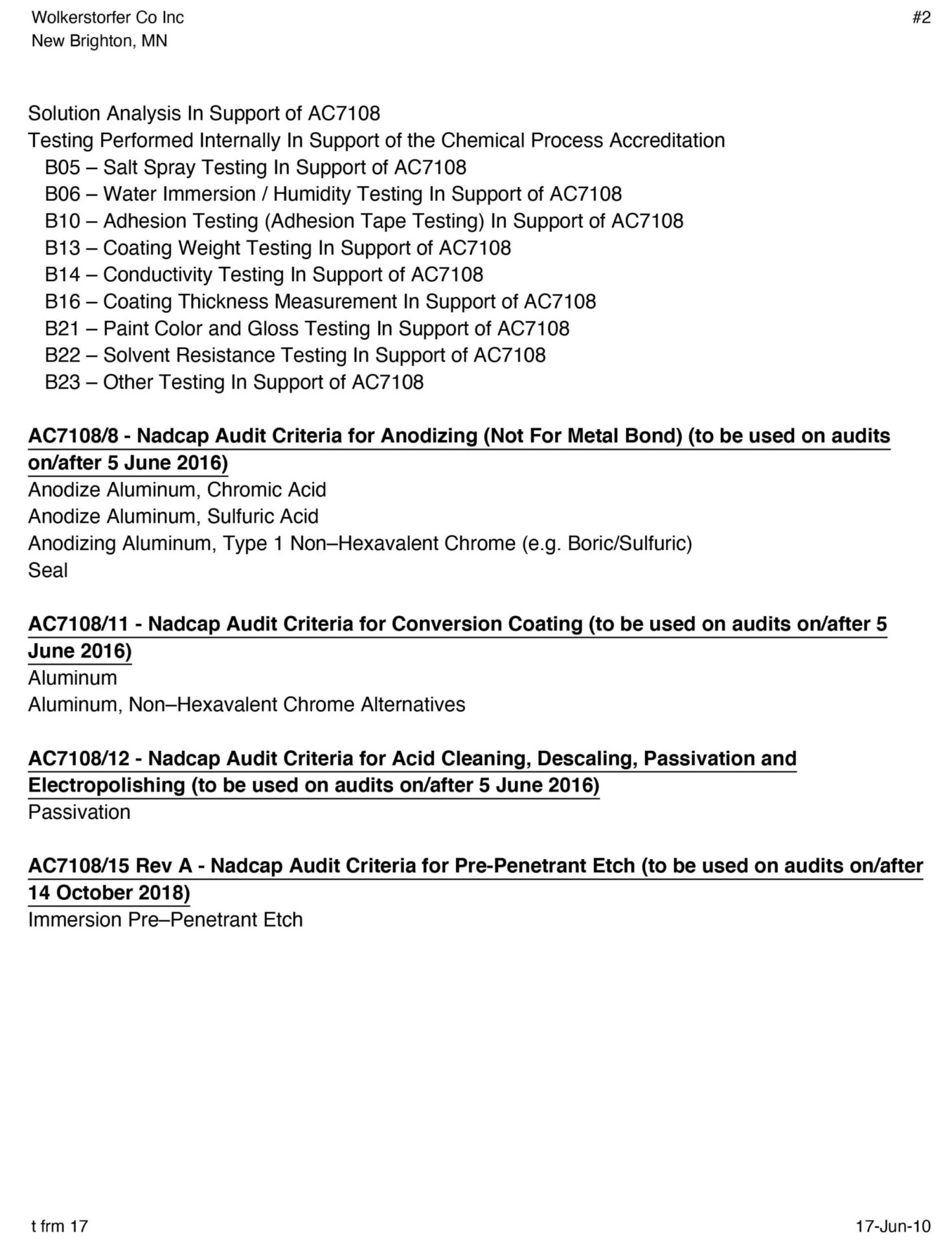

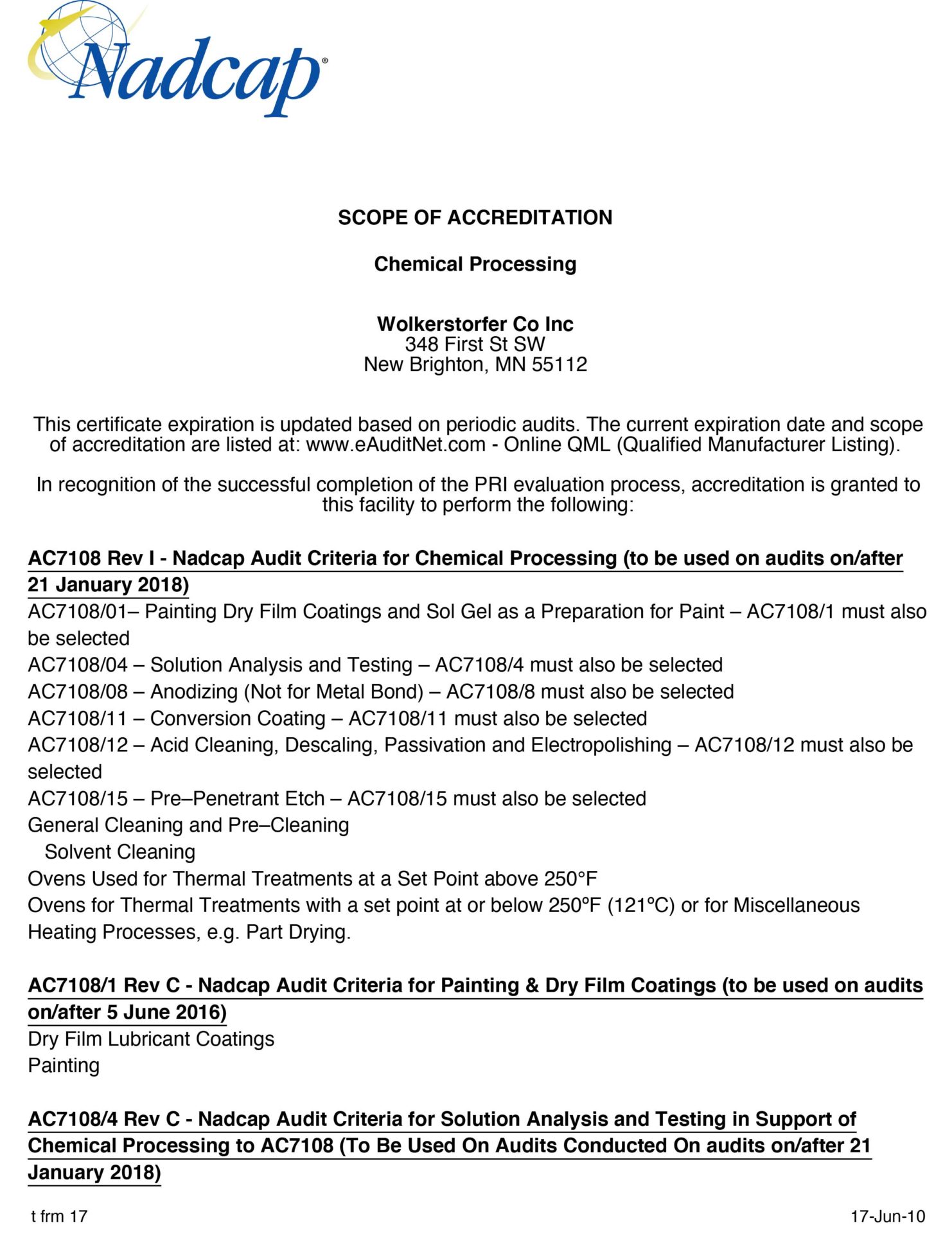

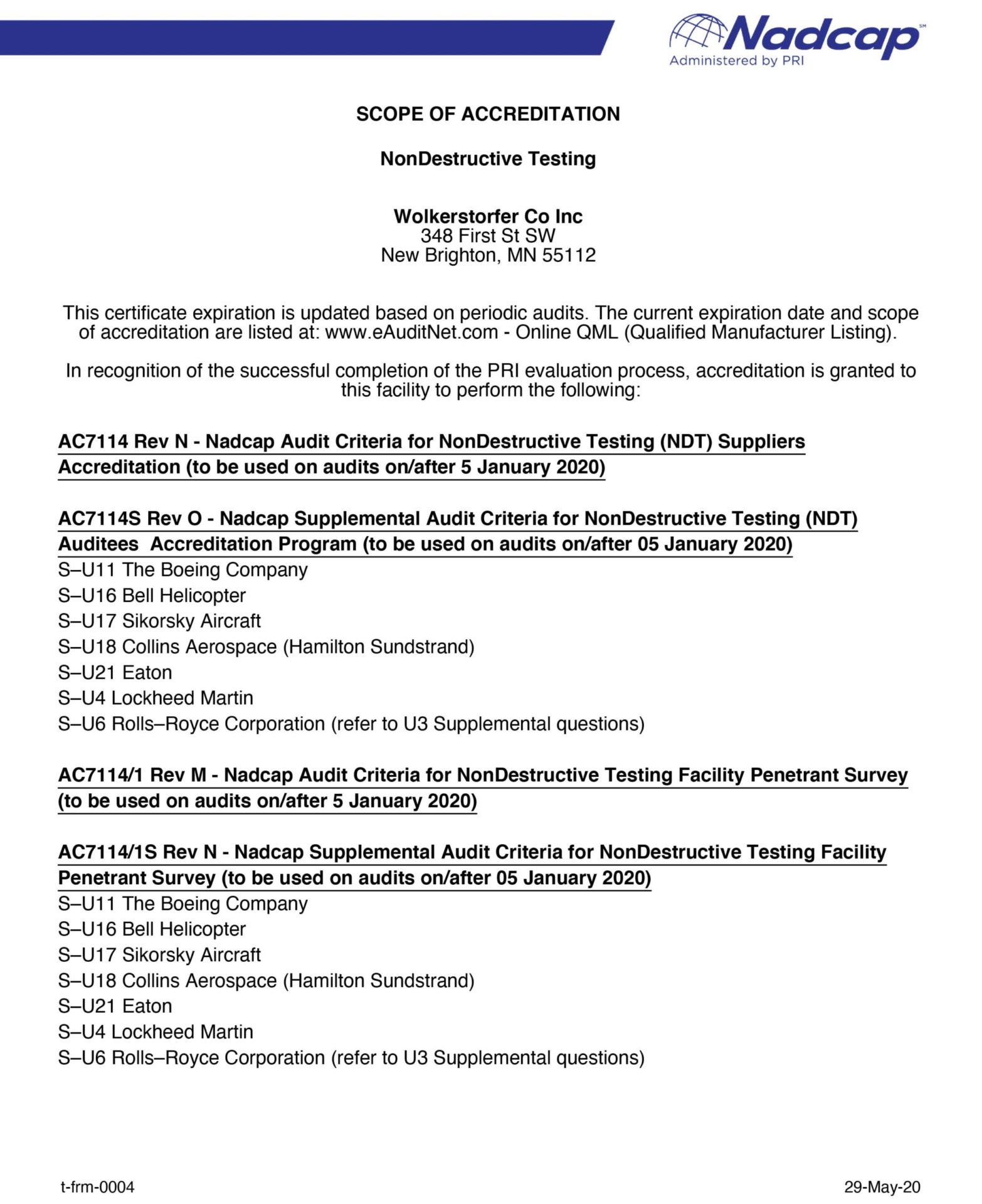

Nadcap

Nadcap is the National Aerospace and Defense Contractors Accreditation Program. Nadcap is a global cooperative accreditation program for aerospace engineering, defense, and related industries. This quality initiative is designed to provide superior performance and standardization across all platforms.

CARC

Chemical Agent Resistant Coatings were developed to protect military vehicles from chemical agents. This paint system is engineered to be easily decontaminated after exposure to chemical and biological warfare agents, and also protects against radioactivity.

Topcoat

The topcoat provides the color and the primary function for the coating. Corrosion and wear resistance would be two examples of the function required of this coating.

Primer

The function of the primer is to increase the bond strength of the subsequent topcoat to the surface, increases paint durability, and/or provide an extra layer of corrosion protection.

Wash Primer

A wash primer is an organic coating typically containing phosphoric acid and zinc chromate. The acid provides a slight etch on the part while the zinc provides modest corrosion resistance. This is often followed by a secondary primer and top coat system.

Paint

Paint is any pigmented liquid that after application to most substrates turns to a thin solid film. It is most commonly used to provide corrosion protection, color, or provide texture to objects.