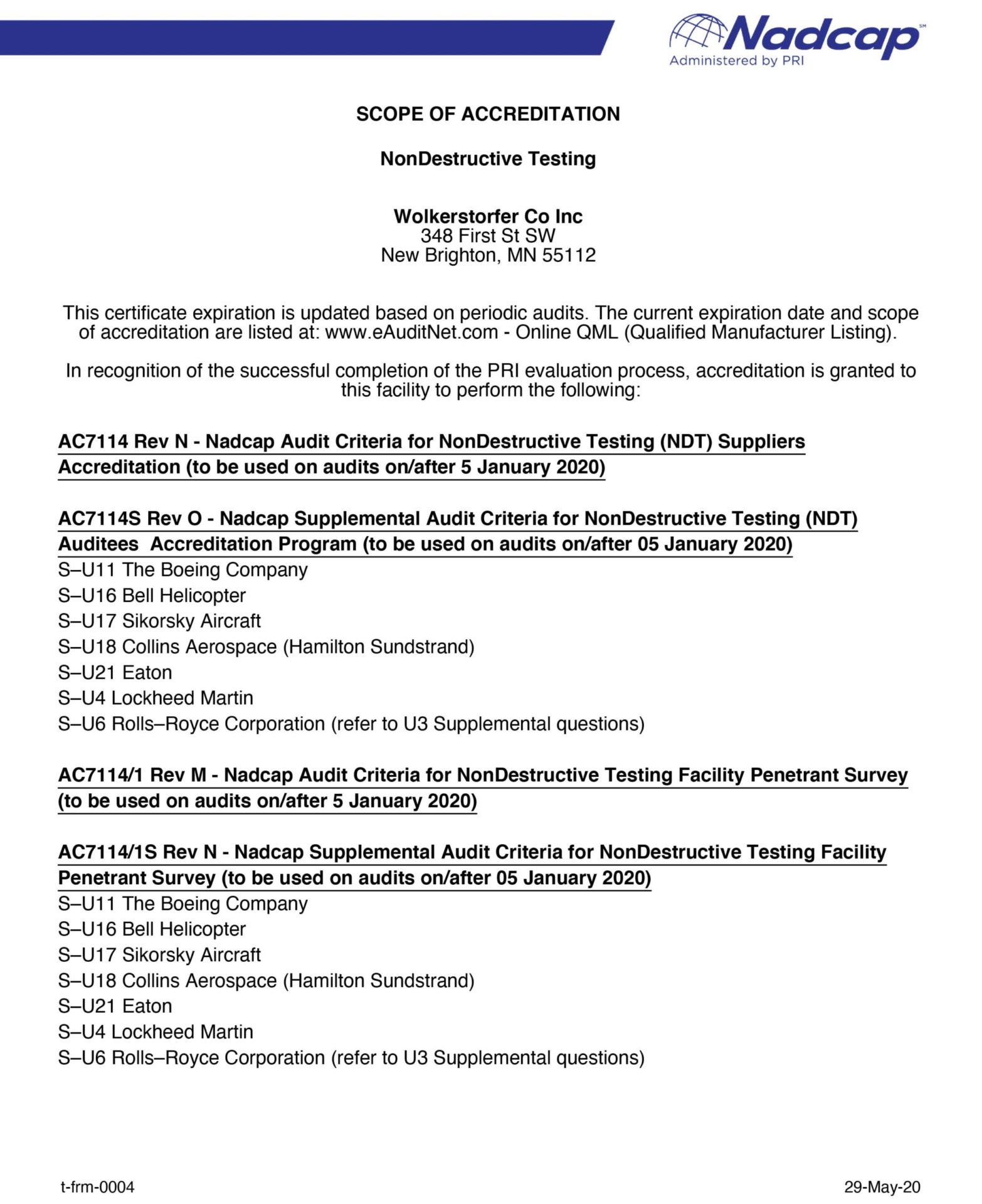

Collins Aerospace Hamilton Sundstrand Liquid Penetrant Inspection Specification

Archives

Teflon™

A trade name for polytetrafluoroethylene. This synthetic resin provides excellent lubricity under light loads.

Pre-Penetrant Etching

During the pre-penetrant process an etch is often used to remove any soft metal smears or residual trace metals left behind from the manufacturing process allowing the indications to be more easily identified. In the case of aluminum, depending on the specification the amount of metal removal is in the .0002” to .0004” range per side.

Liquid Penetrant Inspection

MIL-STD-1907

This specification provides the needed criteria for what visual imperfections are acceptable or not during the inspection process.

Fluorescent Penetrant Inspection

Also called Liquid Penetrant Inspection or FPI. This test system involves the use of penetrating solutions and subsequent developers to expose surface imperfections to the naked eye under ultra-violet light.

NonDestructive Testing

There are two types of testing for materials: Destructive which involves actually destroying a part in order to test its physical characteristics and NonDestructive which allows a person to test a component in such a way as to allow it to still be used in the field.