Nadcap Chem Film

A chromate conversion coating is applied to an aluminum alloy to slow or even prevent corrosion and/or provide a pretreatment for a subsequent paint system. Also called chem film, this nonelectrolytic coating is conductive and is extremely thin (<0.000050″). One of the unique properties of Type I (hexavalent) chem film is that it has a self-healing property when scratched. The film has the ability to “re-passivate” the affected area to continue to provide some corrosion protection. Today, this technology is offered as a hexavalent system or the more environmentally friendly trivalent version.

Wolkerstorfer Company has made a concerted effort to be at the forefront of offering this technology. We have some of the largest tanks and capacity in the Midwest and offer complete processing and testing capabilities to meet most specifications.

Trivalent Chromate Conversion Coatings (RoHS/ WEEE/ ELV)

MIL-DTL-5541, Type II, Class 1A or 3

Sikorsky: SS8486, Type II, Class 1A or 3

Chromate conversion process use chromium compounds, including hexavalent chromium, which is toxic, carcinogenic and hazardous to human health and the environment. Hexavalent chromium is highly regulated and is prohibited by the European Union. In response to this in 2006 the chemical industry developed trivalent chromium (Cr+3) chemistries that are more environmentally friendly and equally effective. The coating meets the European standard RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment), as well as automotive’s ELV (End of Life Vehicle Directive). We have a total of 3,700 gallons collectively in house. Please reference our Facilities drop down for specific dimensions.

Hexavalent Chromate Conversion Coatings

MIL-DTL-5541, Type I, Class 1A or 3

Boeing: BAC 5719, Class A or D

Rockwell Collins: 580-0036

Gulfstream: GAMPS 6113

Hamilton Sunstrand: HS 240

Bell Helicopter: BPS 4182, Class 1A or 3

Conversion coatings for aluminum that contain hexavalent chromium (Cr+6) offer excellent corrosion inhibitors and is the primary chemical in most traditional chem film baths. The appearance of the coating can be a yellow/ gold to an iridescent color. Wolkerstrofer Co. operates some of the largest tanks in the Midwest, with a total of over 11,000 gallons collectively in house. Please reference our Facilities drop down for specific dimensions.

Bleached Chromate Conversion Coatings

Raytheon: H314543

Similar to MIL-DTL-5541, Class 1A this hexavalent chem film process was developed by Raytheon. It maximizes the corrosion resistance while minimizing the electrical surface resistance to no more than 15 ohms after 168 hour salt spray testing per ASTM B117.

Largest capacity / tanks in the Midwest

Wolkerstorfer Company has always been known for our ability to handle larger parts. For Chem Film processing we have some of the largest tanks in the Midwest that contain hexavalent chromium (Cr+6) Chem Film chemistry (MIL-DTL-5541, Type I):

30 feet long x 3 feet wide x 3 feet deep

16 feet long x 16 feet wide x 3 feet deep

12 feet long x 4 feet wide x 6 feet deep

Our newest investment is in trivalent chromium (Cr+3) Chem Film (MIL-DTL-5541, Type II) and can accommodate parts in one of two lines:

30 feet long x 3 feet wide x 3 feet deep

8 feet long x 4 feet wide x 5 feet deep

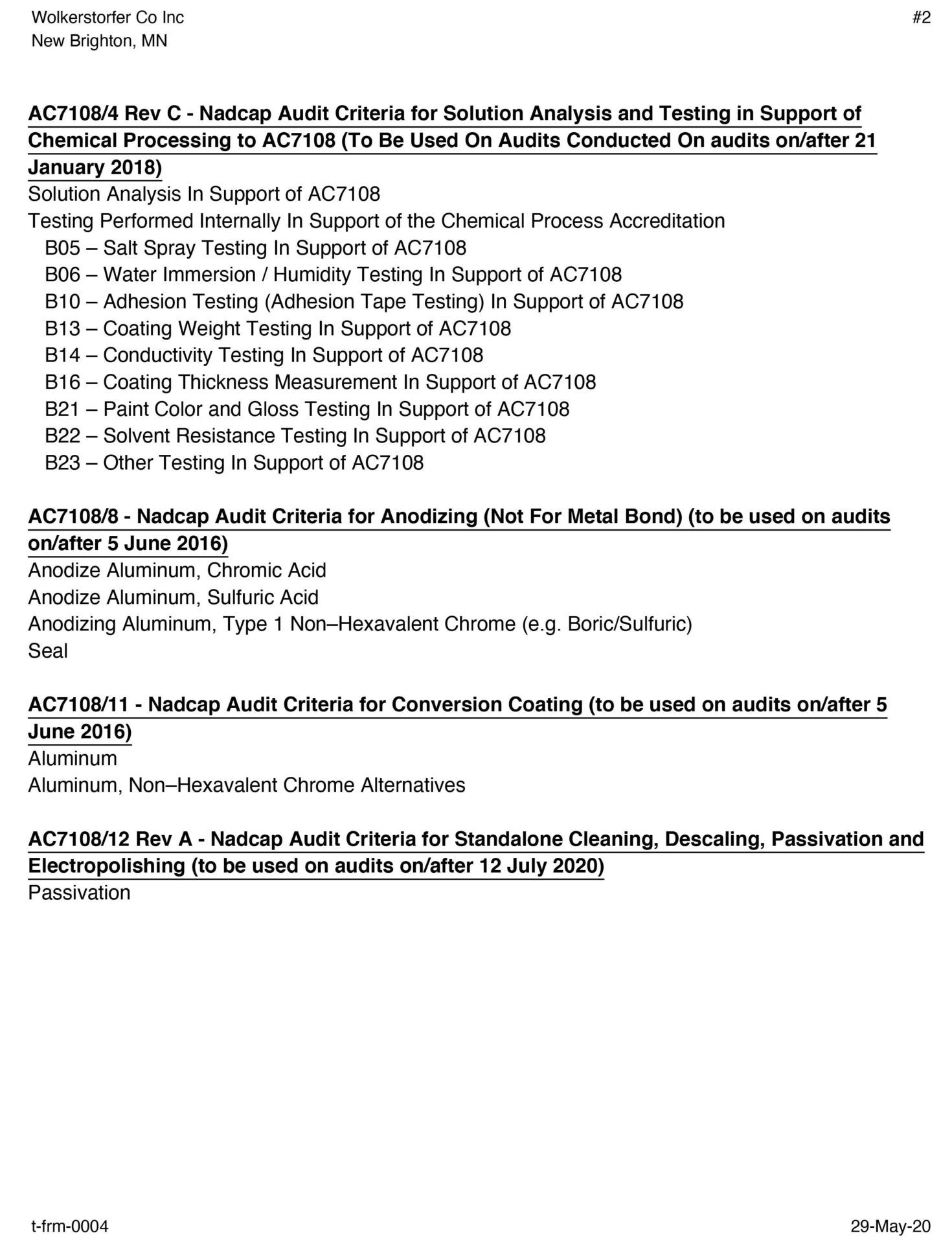

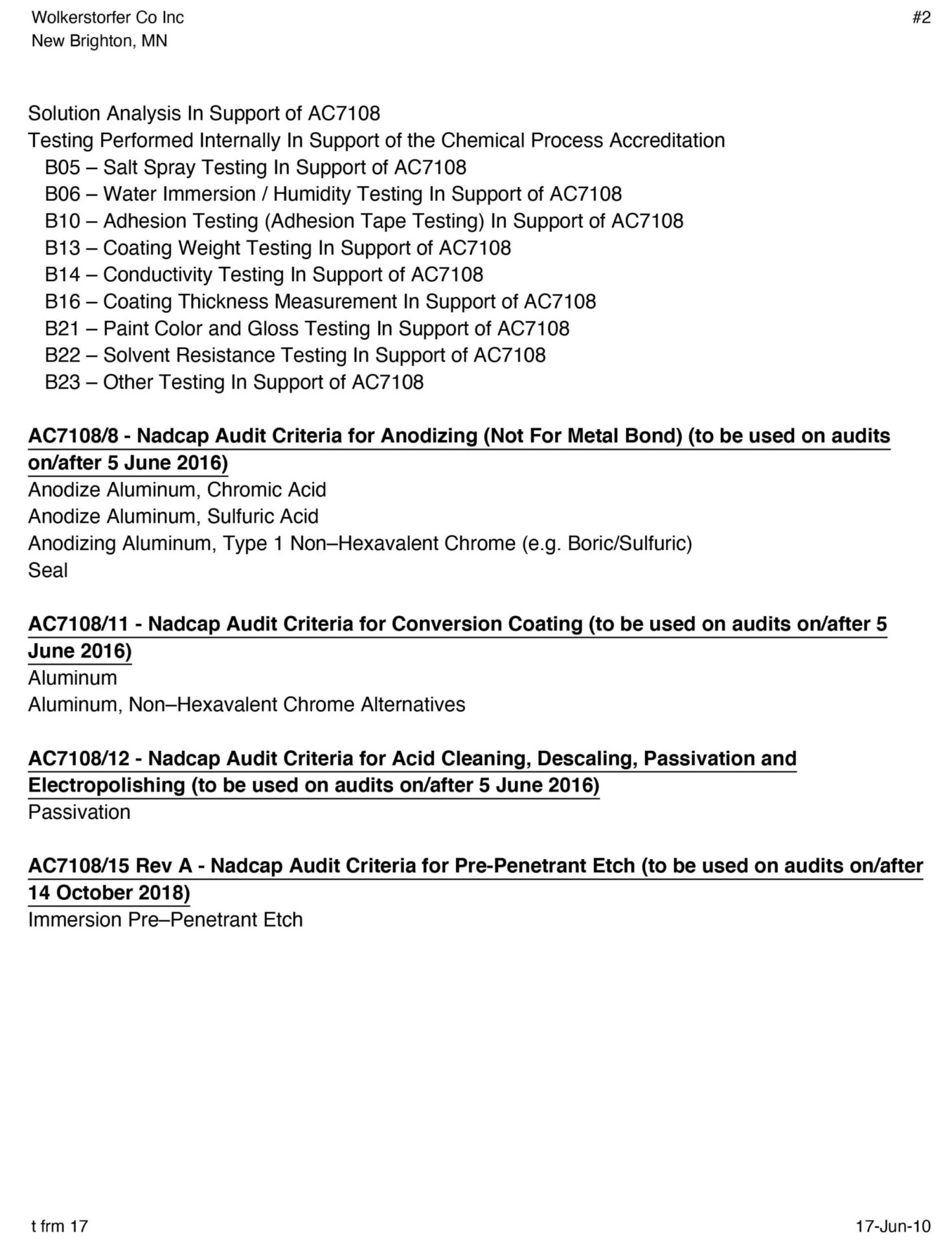

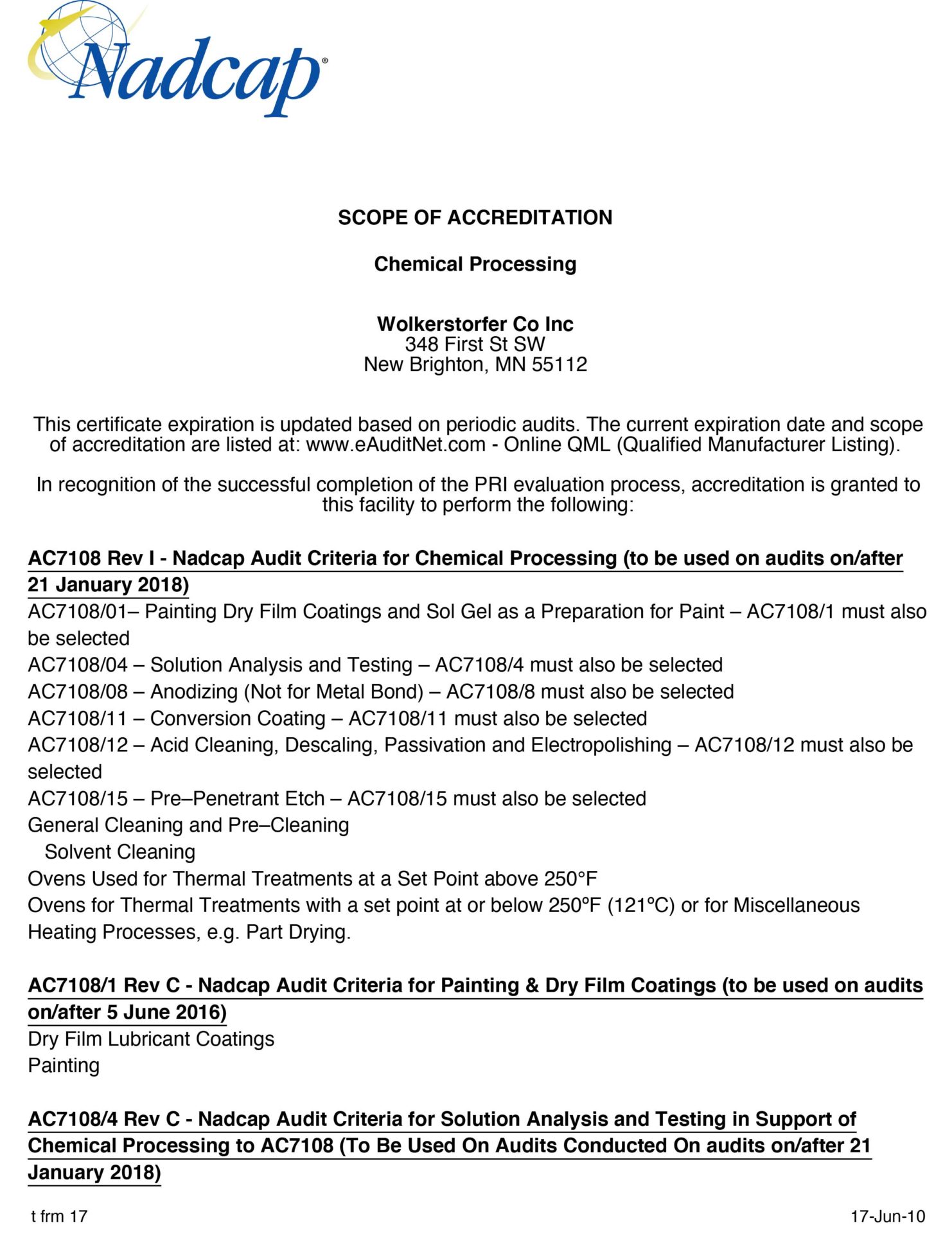

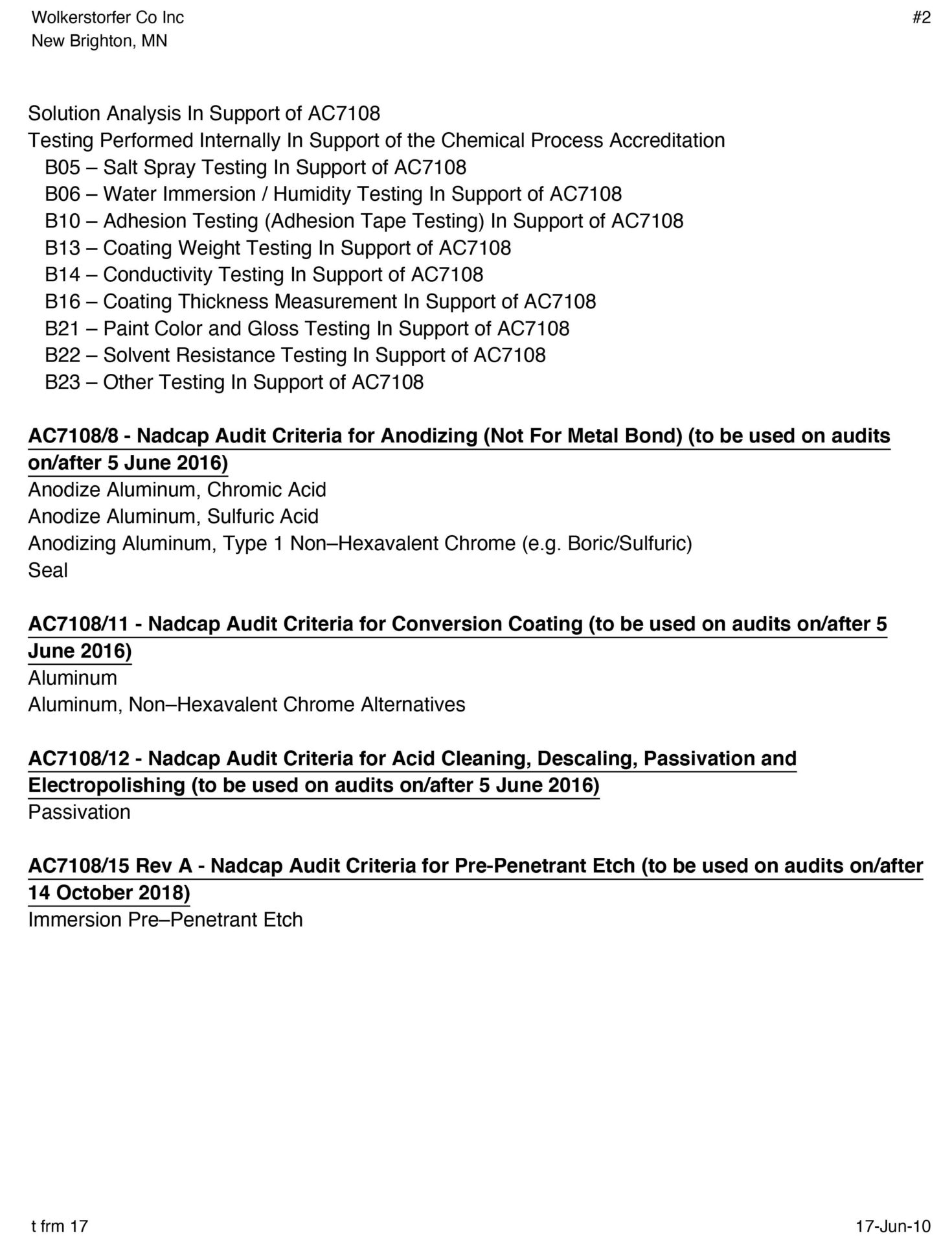

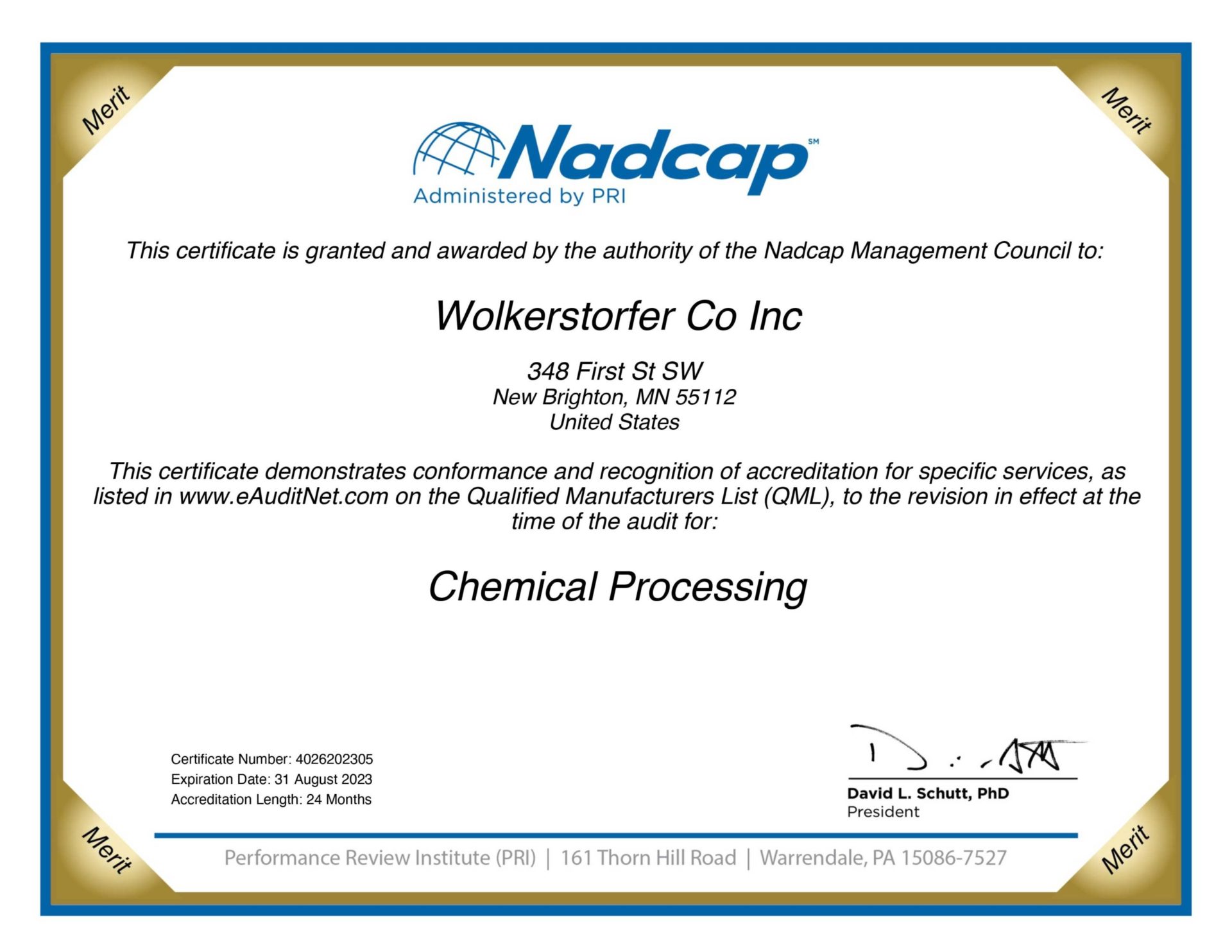

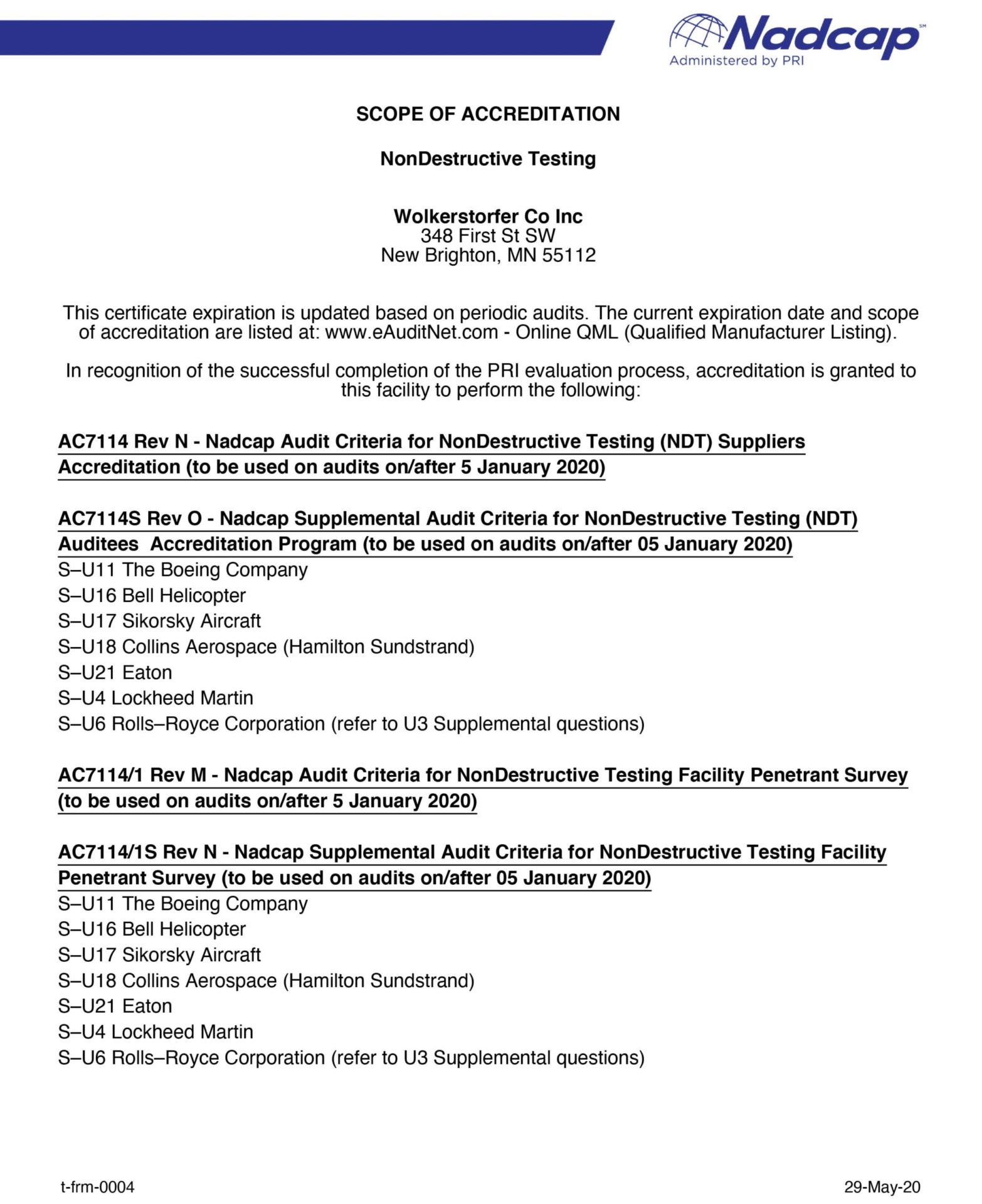

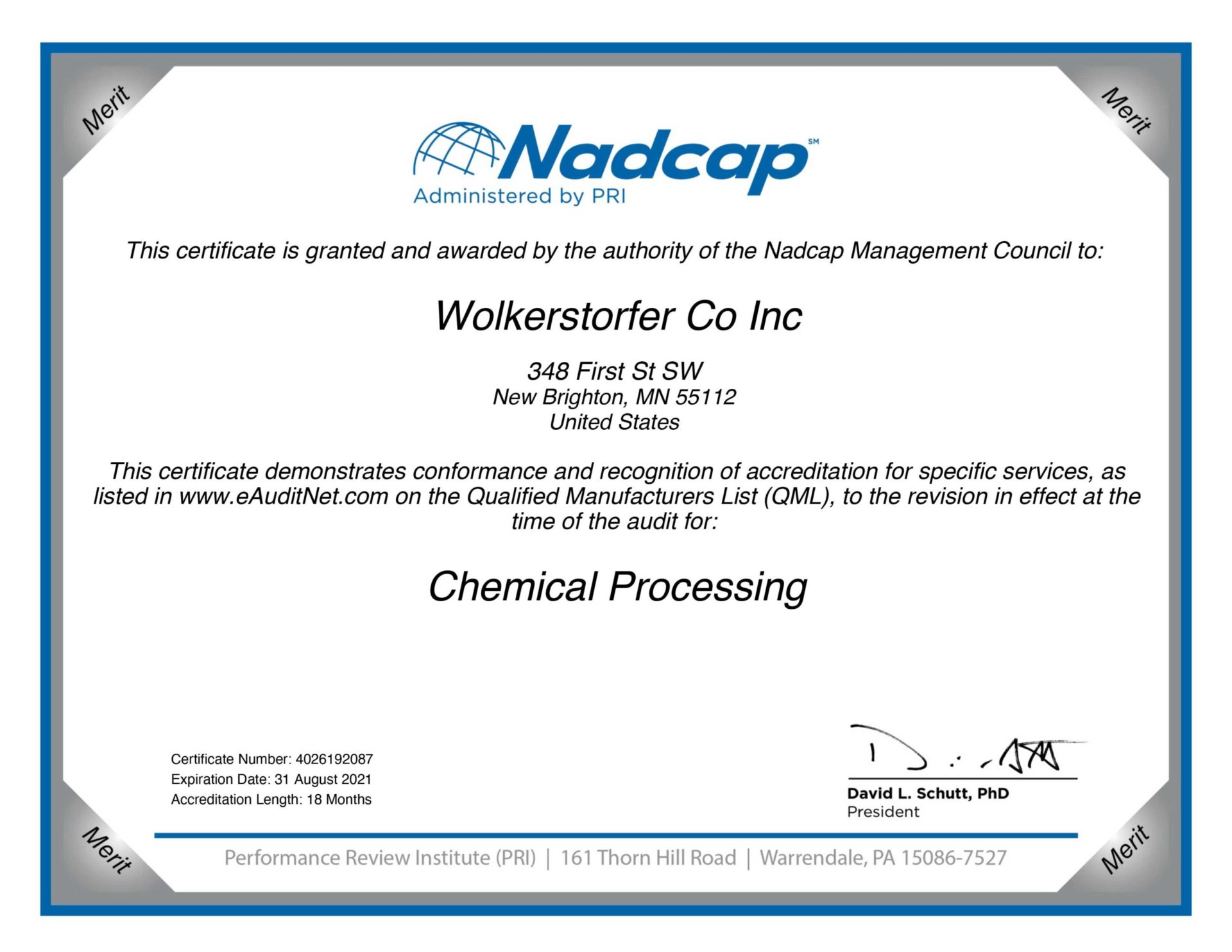

Click here to view a copy of our Nadcap Certifications.