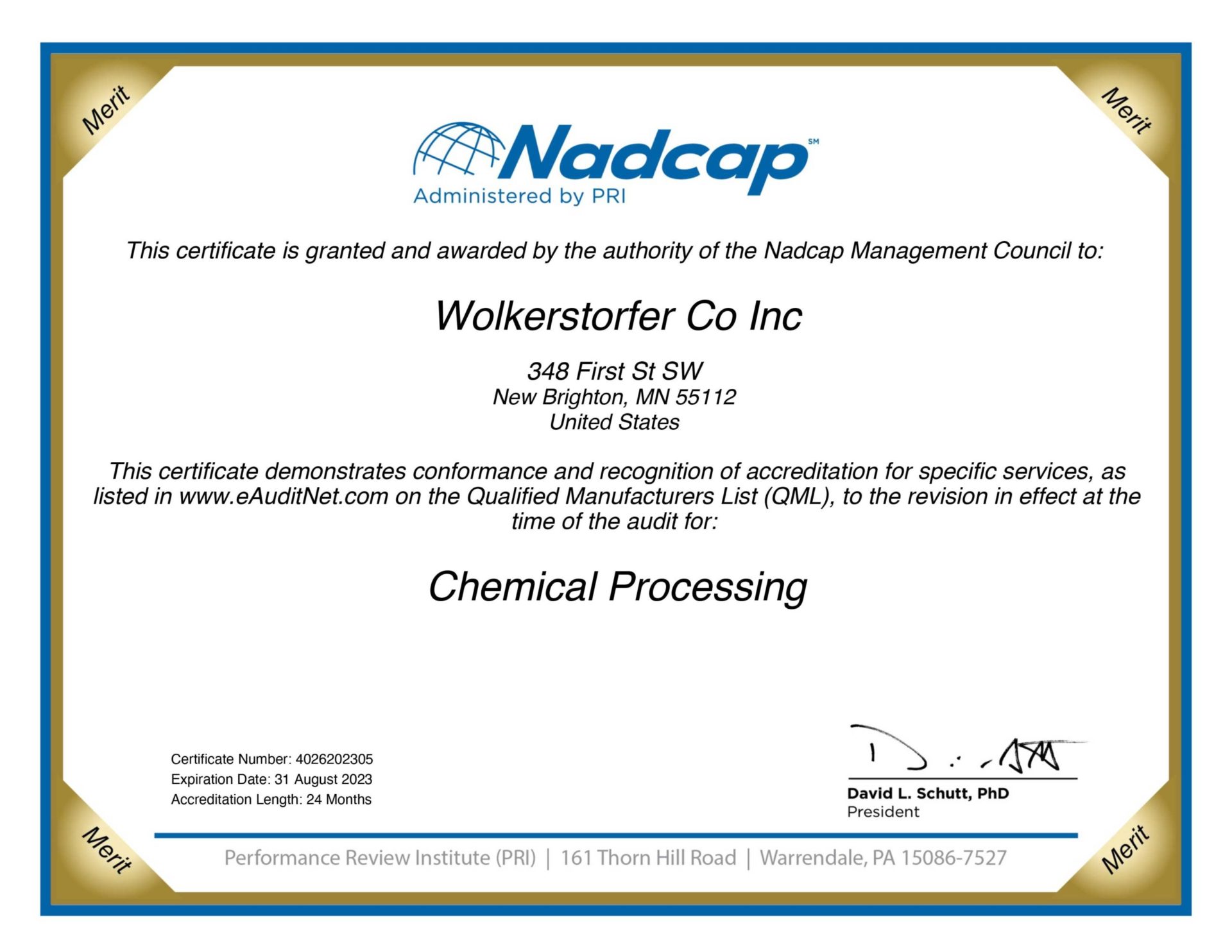

NADCAP Certified Aluminum Anodizing

There is often confusion between electroplating and anodizing. Despite their apparent similarities, electroplating and anodizing serve different functions. Similar to armor, electroplating adds a layer of one metal on top of another. Anodizing, on the other hand, strengthens a metal by thickening the oxide layer on its surface. For example, anodization provides aluminum with a harder aluminum oxide surface that improves durability and protection. Using a variety of different acid solutions, which create different anodic coatings, our Nadcap anodizing has the ability to meet stringent criteria for corrosion protection and electrical conductivity. We offer sulfuric acid and the Boeing patented boric-sulfuric acid anodizing processes with a number of different sealing solutions.

Boric-Sulfuric Acid Anodize (BSAA)

MIL-A-8625, Type IC

MIL-PRF-8625, Type IC

Boeing: BAC 5632

For environmental reasons, Boeing Aircraft developed boric-sulfuric acid anodize to replace chromic acid anodize. Unlike traditional sulfuric acid anodize, the coating is very thin, comparable to the chromic acid anodizing it is replacing. Wolkerstorfer Company is a licensed applicator of this Nadcap anodizing coating, which meets MIL-PRF-8625, Type IC and Boeing’s BAC 5632. We are capable of processing parts up to 10 feet in length and 2,000 pounds. We are Nadcap certified for this process.

Sulfuric Acid Anodize (SAA)

AMS 2471

MIL-A-8625, Type II and IIB

MIL-PRF-8625, Type II and IIB

Rockwell Collins: 580-0008

Sikorsky: SS 8483

Sulfuric Acid Anodize is a coating that provides better abrasion resistance than the other typical anodize systems, with the exception of hardcoat. Meeting MIL-PRF-8625, Type II and IIB, SAA provides an excellent pretreatment for various paint and dry film systems. our Nadcap anodizing team is capable of handling parts up to 8 feet in length and 2,000 pounds in weight. We are Nadcap certified for this process.

Post Anodize Seals

At the completion of the Nadcap anodizing process there are a number of seal options to consider. A fresh anodized surface is an anhydrous oxide that is hydrophilic, or simply put, a coating looking to be wetted. Wetting can occur through immersion but also from the moisture in the air, hence the reason to move quickly with the fresh anodize surface. Typically a “sealing” process is called out on the print or specification. Each coating has certain favorable traits, depending on the type of anodizing system used. We offer nickel acetate, hot water and dilute chromic acid seal systems to meet a variety of aerospace and military specifications.

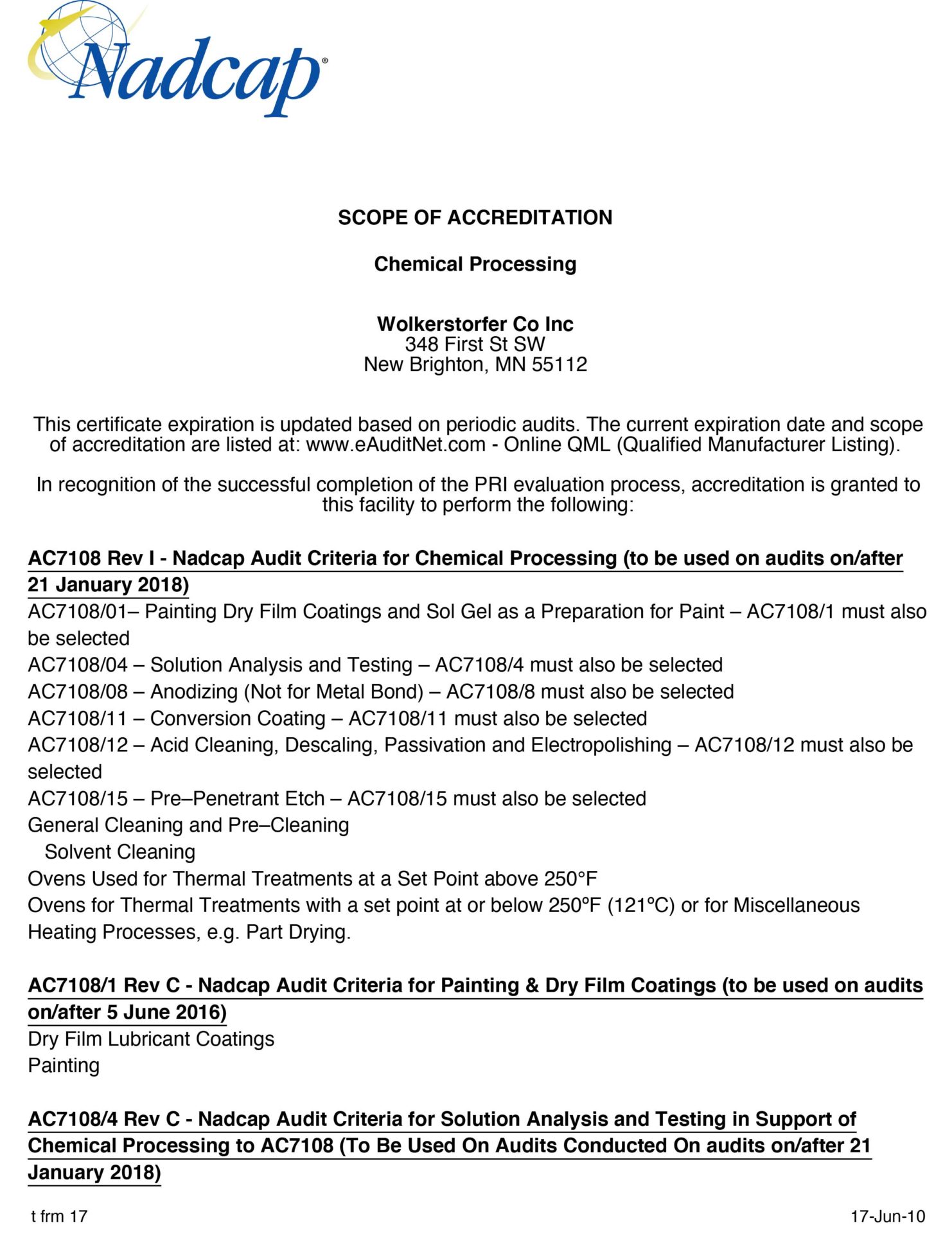

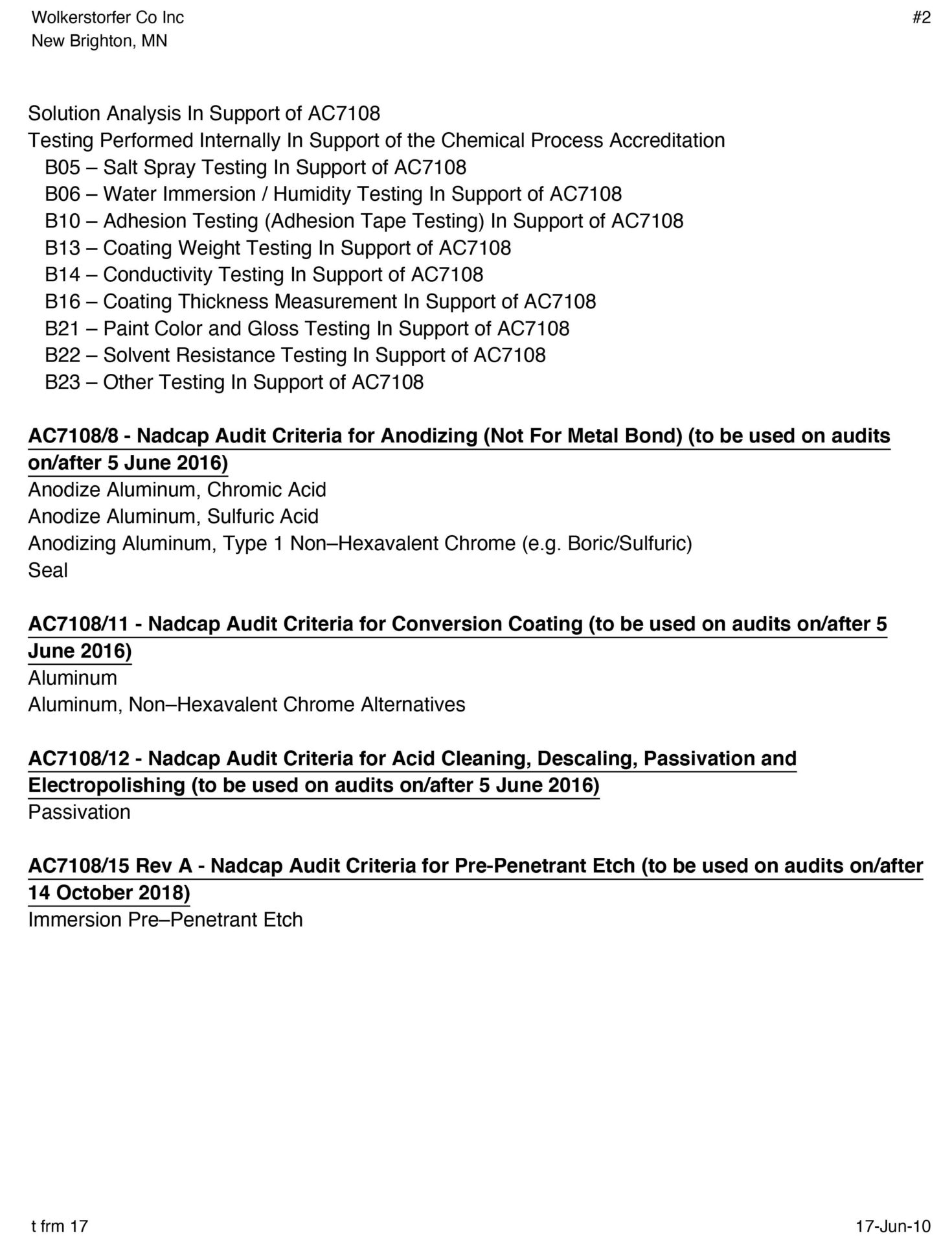

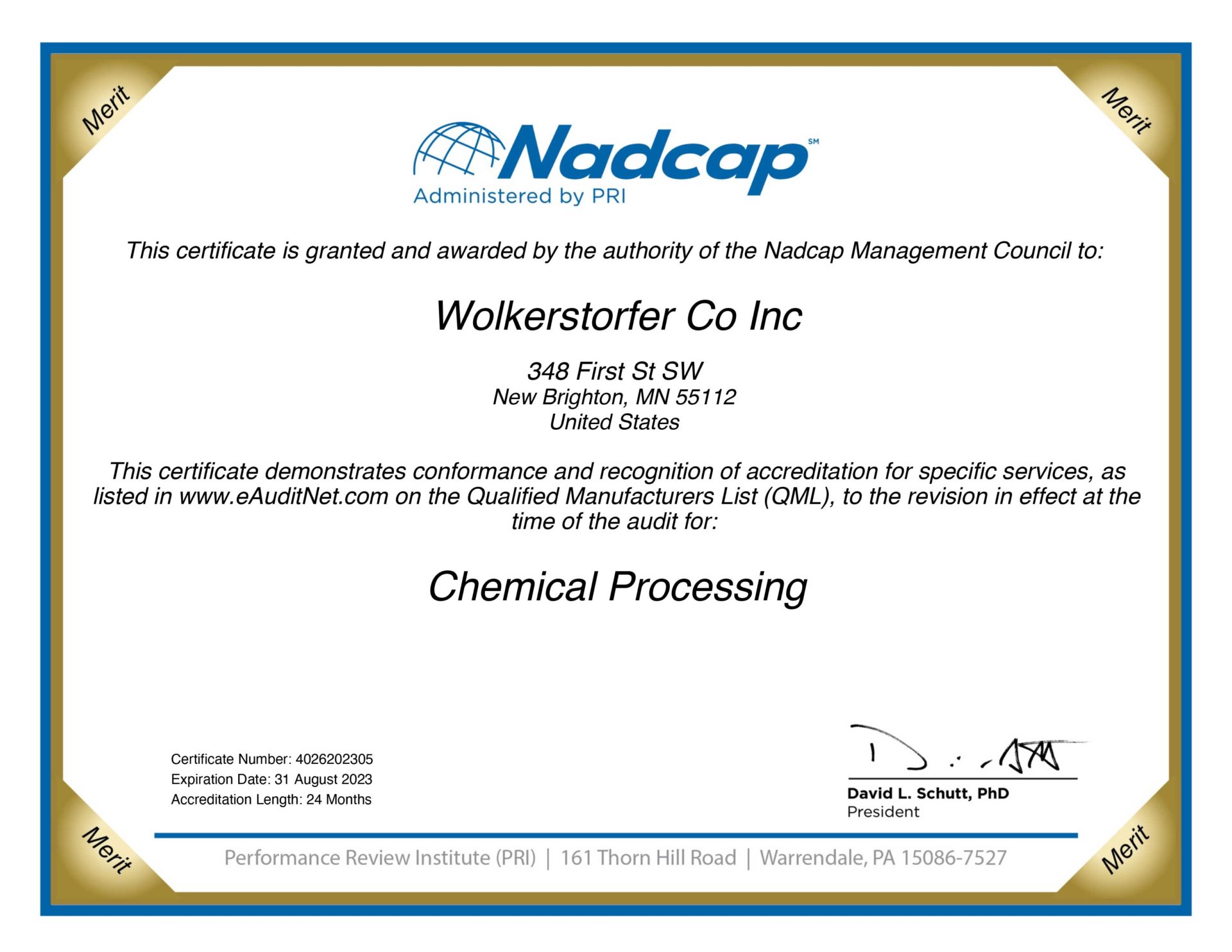

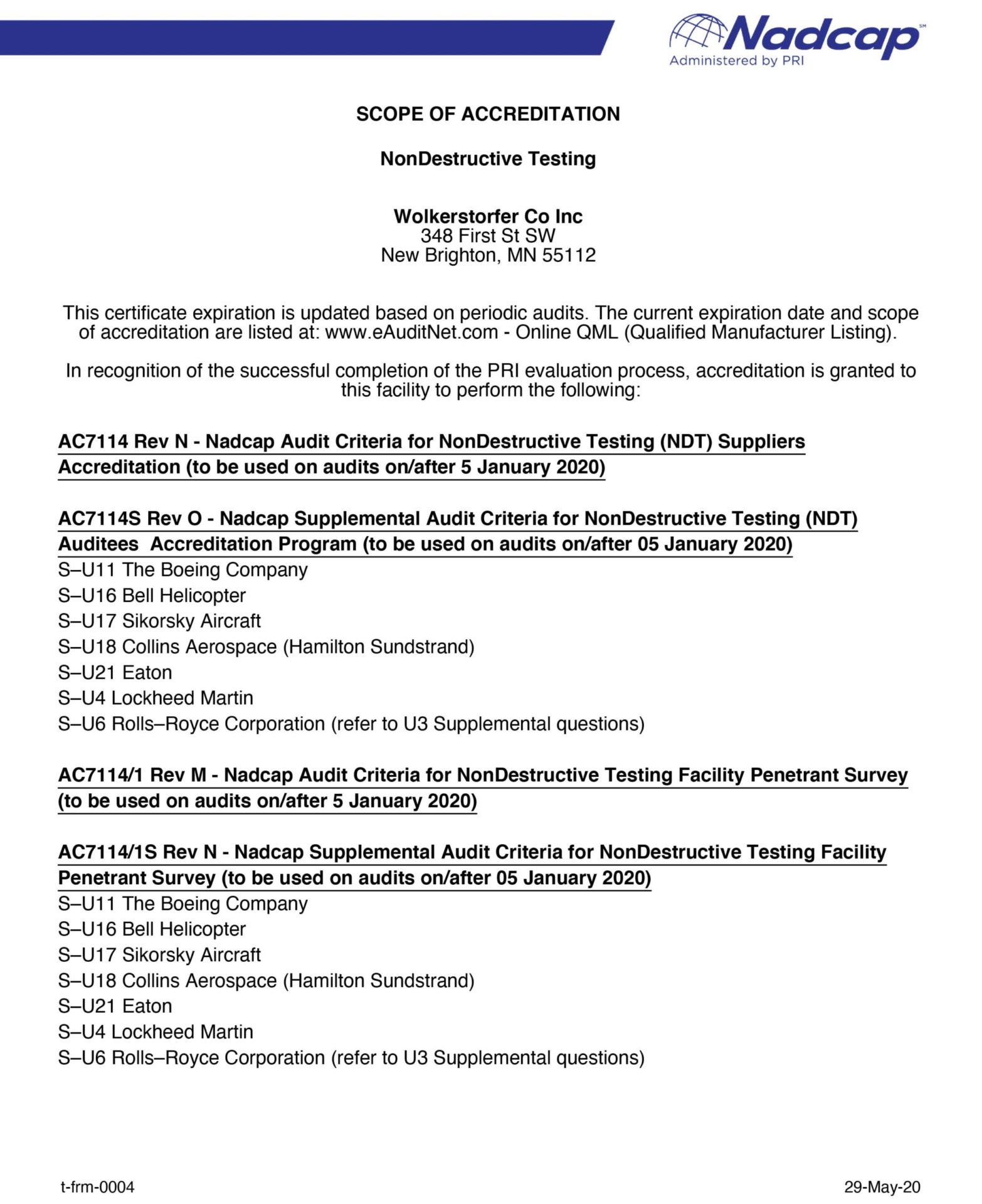

Click here to view a copy of our Nadcap Certifications.